5 Axis CNC Rotary Table

High Quality 5th axis rotary table For Multi-axis Machining From China Manufacturer - SilverCNC

Looking for high-quality 5 axis cnc rotary tables? Look no further than SilverCNC! Our full range of rotary tables can be seamlessly integrated into nearly any machine tool brand to achieve simultaneous 5-axis or 3+2 multi-angle machining, greatly enhancing the accuracy and efficiency of your parts machining.

Precision, quality, and stability to meet your requirements, and our affordable pricing and exceptional after-sales service will ensure your complete satisfaction.

Features of Our 5 axis cnc Rotary Table

- Wide Compatibility: Integrates seamlessly with Haas, DMG, Mazak, and more.

- Customizable Design: Customize your 5-axis machine with SilverCNC.

- Unmatched Precision: High-performance encoders deliver exceptional accuracy.

- Low Maintenance: Durable roller cam structure ensures reliable, low-maintenance operation.

Enhance Your Machining with SilverCNC's Universal 5-Axis Rotary Table

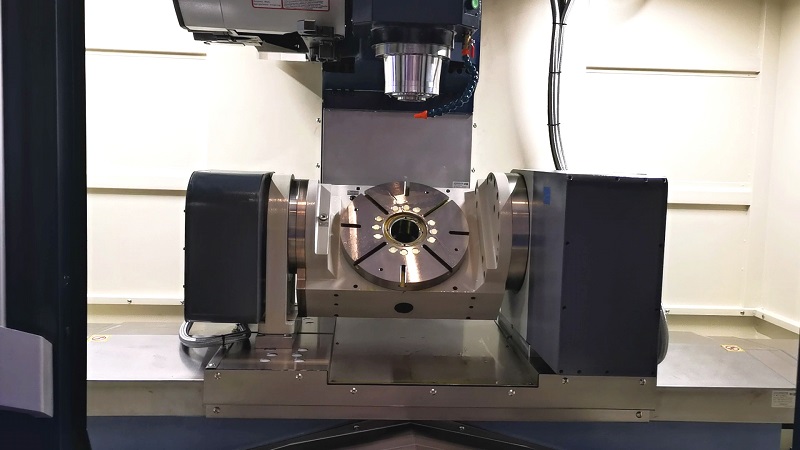

SilverCNC’s 5-axis rotary table offers seamless compatibility with leading CNC machine brands and controller systems, including DMG, Haas, Hurco, Fanuc, and Brother. Designed for versatility, it pairs with the ideal motor and driver for your setup, enabling precise and efficient simultaneous 5-axis machining. Optimize your workflow and achieve superior results with this advanced solution.

Affordable 5-Axis Machining Made Easy with SilverCNC

5 axis machining offers unmatched benefits for producing complex and precise parts, such as enhanced precision, reduced setup time, improved surface finish, and minimized tool wear.

However, upgrading a 3-axis machine to 5-axis capability can be prohibitively expensive. For instance, adding a Haas TR160 5-axis table could cost over $40,000—an investment many find daunting.

SilverCNC provides the perfect solution. Our 5-axis rotary table delivers reliable performance, stable quality, and high accuracy—all at a fraction of the cost. Elevate your machining capabilities without overspending with SilverCNC.

5 axis CNC Rotary Table Series

SilverCNC’s 5 axis CNC rotary table models named after their rotary platter diameter. Customize your platter diameter with some of our models. Contact our sales representatives for detailed information

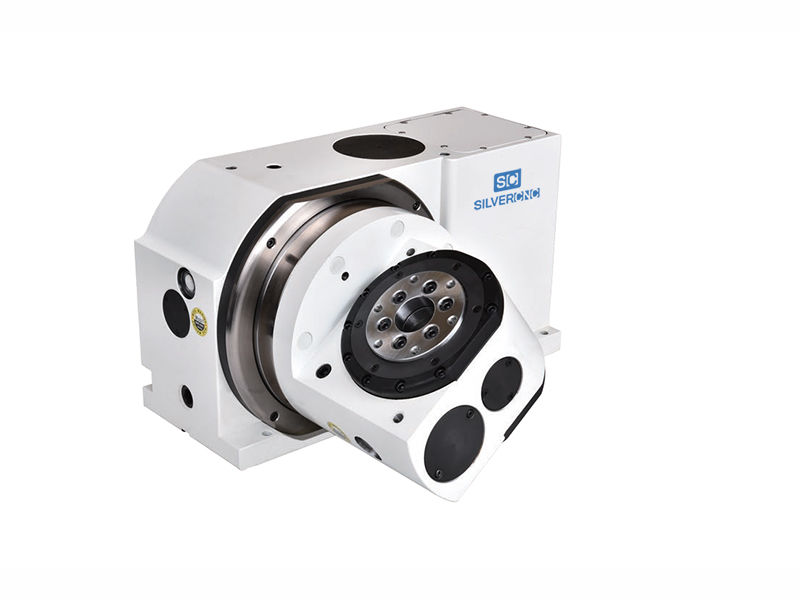

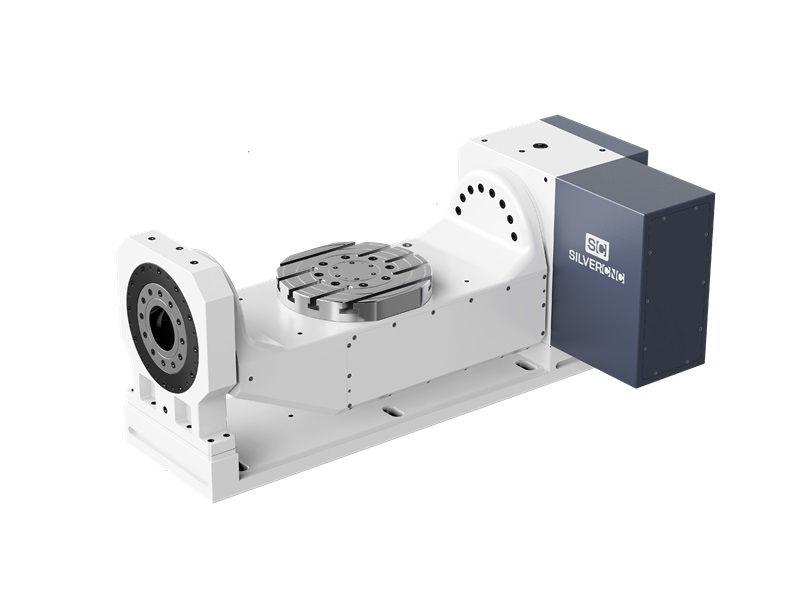

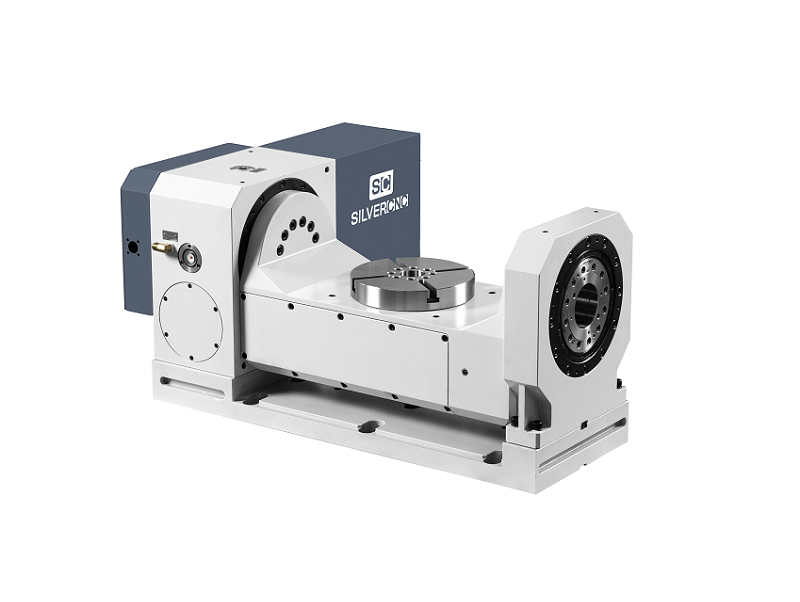

200mm Cradle Structure

T-slot plate can be customized, maximum rotation diameter is 460mm, machining range is expanded

Best selling model

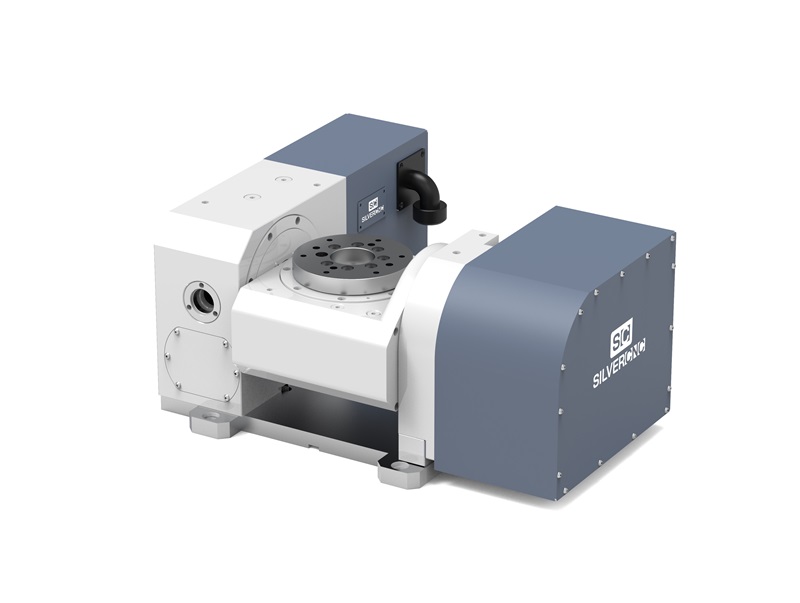

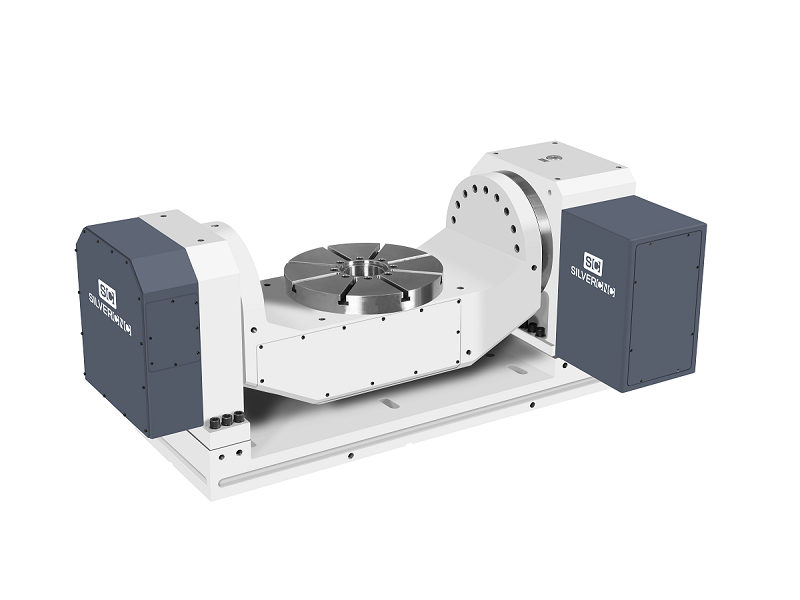

250mm Trunnion Table

High rigidity, can installed as A+B type 5th axis rotary tabe, suitable machine tools include: Haas VF3, DMG1100X, and other 1000mm travels VMC

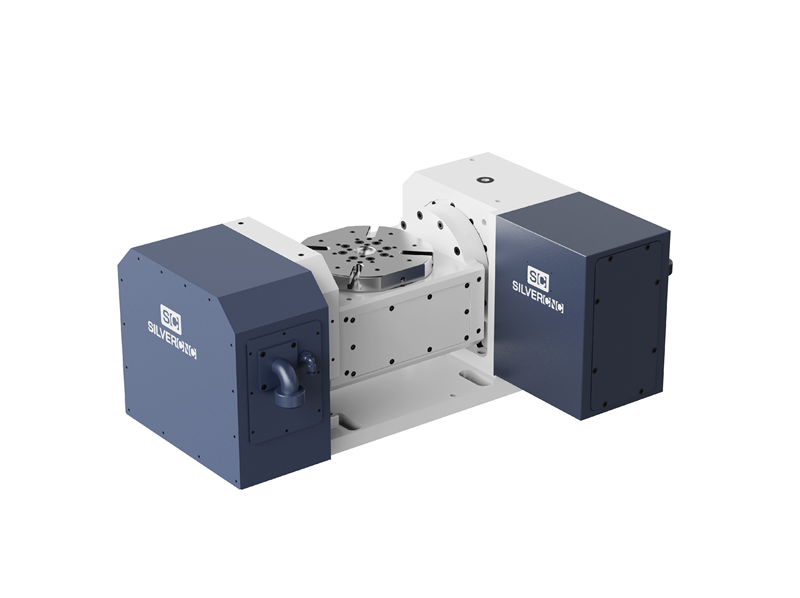

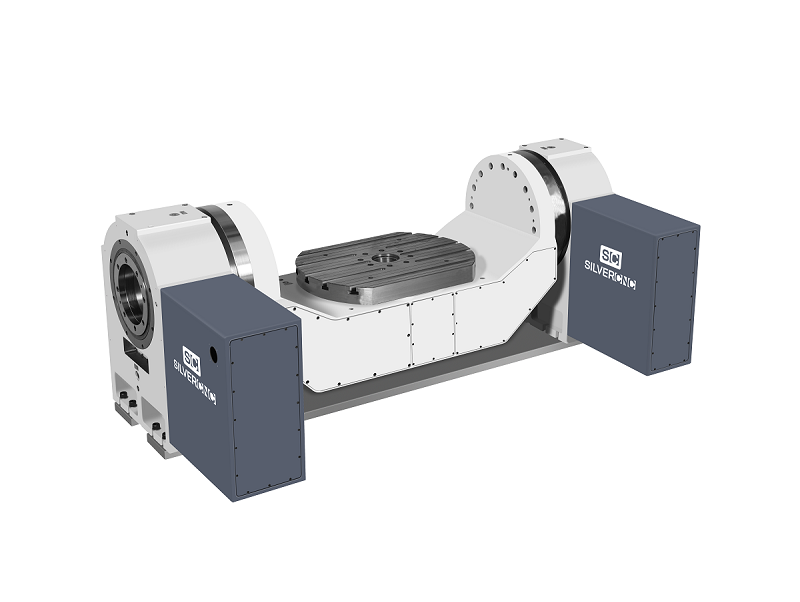

400mm Rotary Table

Cradle structure design, The machining range can reach 740mm, which is used for super-large vertical machining centers or gantry machining centers

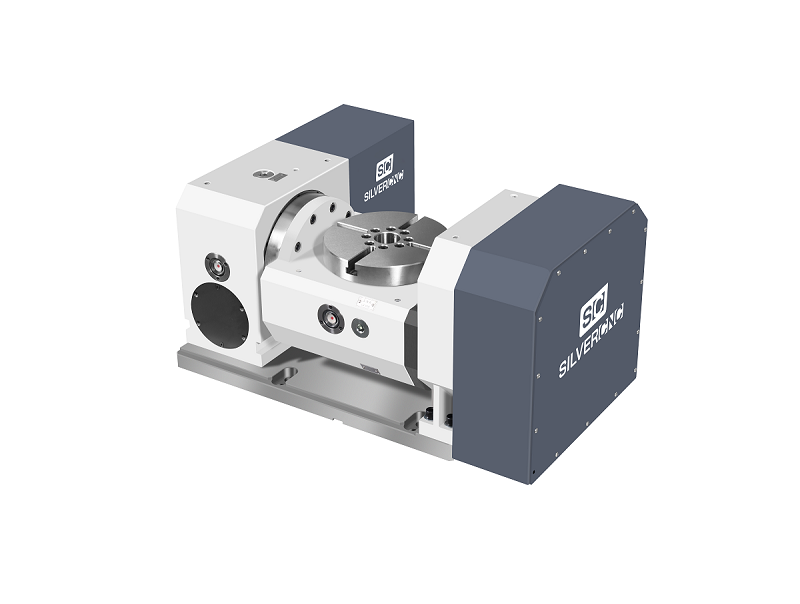

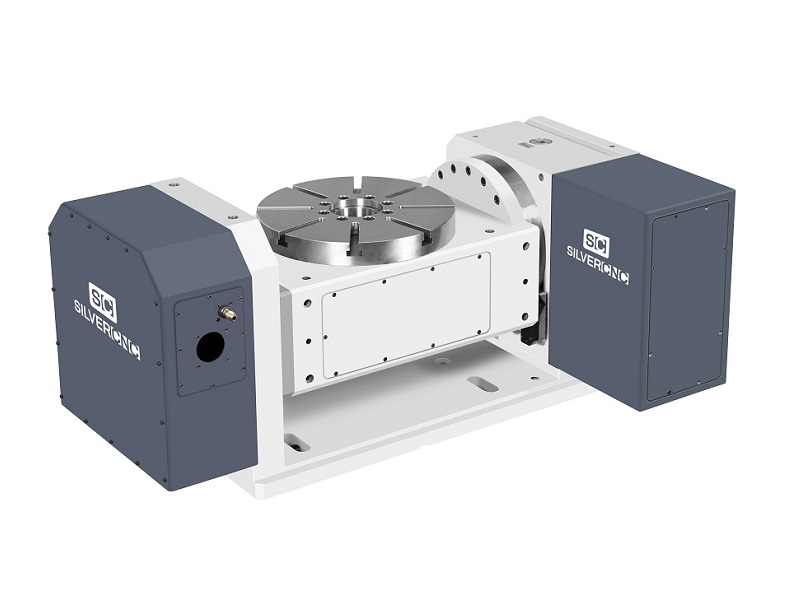

650mm rotary table, platter can be customized

Double-drive (4-axis and tailstock dual-motor drive at the same time to increase rigidity and torque), which can be designed as a cradle-type 5 axis machine tool in cooperation with the machine tool manufacturer

Download Specifications and technical documents

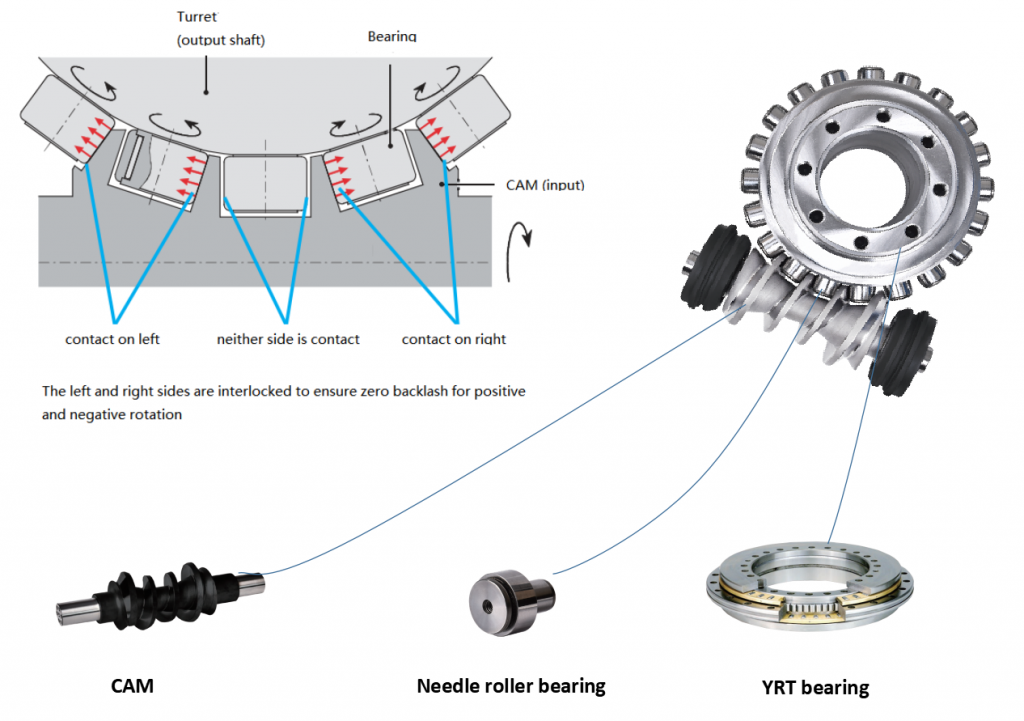

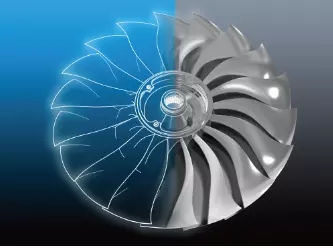

Zero backlash technology in 5th axis rotary table

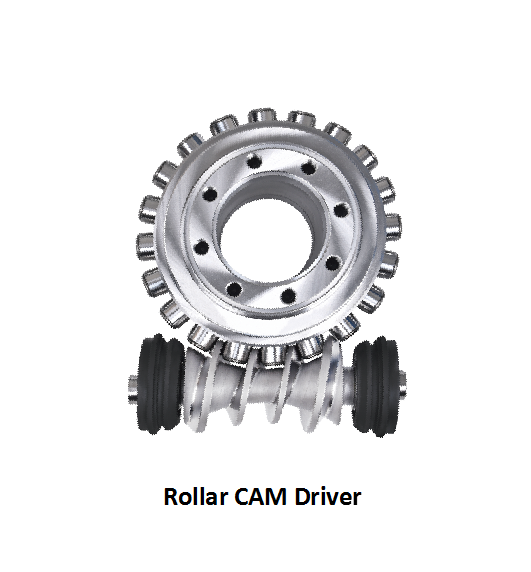

Silvercnc adopts the roller CAM mechanism , one of the finest motion control mechanisms available. The unit is constructed from an input shaft (the roller gearcam) and a turret (output shaft) fitted with roller followers.The roller followers are preloaded against a screw-like input shaft to completely eliminate backlash. Our proprietary adjustment mechanism provides optimum preload. The roller followers planted in the turret use internal roller bearings to transfer torque while rotating. This ensures zero backlash, outstanding precision,and excellent efficiency without causing wear, while providing long-term consistent accuracy.

Roller CAM 5 axis rotary table advantages:

The 4th axis rotary table is Widely used in large machining centers. Compared with other structures rotary table, the four axis have the following characteristics and advantages:

1, No backlash

Through the roller and CAM rolling contact, no forward and reverse back gap problem, greatly improve the roller CAM ultra-precision characteristics, reduce the rate of defects, improve the quality of precision machining technology is a breakthrough.

2, Ultra high efficiency conduction

Roller CAM type turntable in rolling way conduction, reduce wear, conduction efficiency is high, high speed operation, conduction efficiency is up to 90% above.

3, There is no thermal displacement

Even under high speed operation, reduce friction, reduce heat displacement, improve quality stability, reduce the rate of defects.

4, Free maintenance

Due to low abrasion and minimal aging, the initial precision can be maintained for a long time.

5, Life is long

Roller conduction mode, can reduce wear, long service life.

6, The brake performance

During the positioning of the brake, the disc surface will not shake from side to side, and the positioning brake will be kept within 2um, which can highly show the precision machining quality.

Tilting Functionality of a 5-axis CNC Rotary Table

A 5-axis rotary table is essentially a CNC tilting rotary table.

The core feature of a 5-axis rotary table is its ability to tilt the workpiece in multiple directions, usually around two axes. This tilting action allows for precise and complex machining from various angles without requiring manual repositioning of the part. It significantly improves flexibility, enabling the machining of intricate shapes, undercuts, and angled surfaces that traditional setups would struggle to handle. This tilting feature streamlines operations, reduces setup time, and increases machining accuracy for high-precision parts.

How does 5 axis rotary table Work?

How to Choose the Right 5 AXIS CNC Rotary Table?

SilverCNC has identified two key factors that influence the selection of a 5-axis rotary table. For more information or any questions, feel free to contact our sales representatives for expert guidance.

1. Machine tool's factors

■ Machine tool table size and travel

5axis rotary table size cannot exceed the size of the workbench.

■ Machine tool bearing capacity

5axis rotary table weight should not exceed the bearing capacity of the machine tool. Considering the weight of the fixture, cutting force, the dynamic performance and the life of the screw guide, we recommend that the weight of the table should not exceed 70% of the bearing capacity of the machine tool.

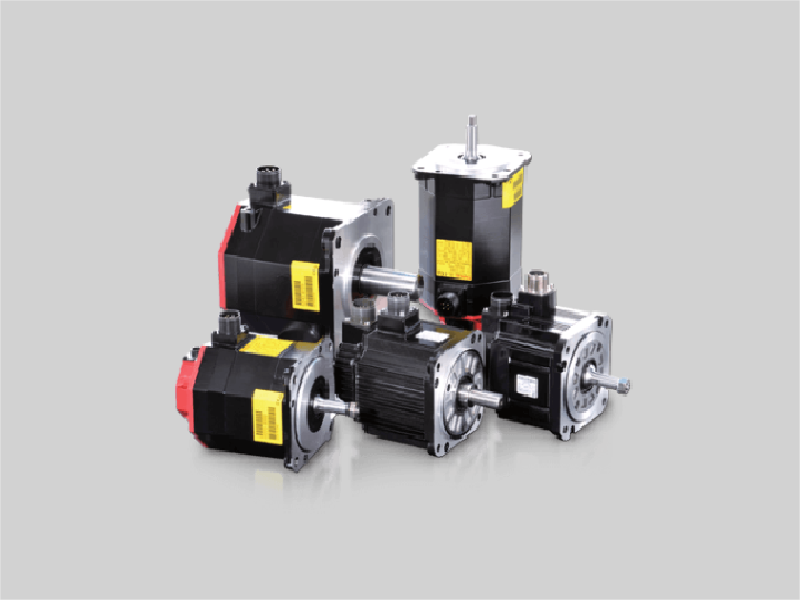

■ Machine tool controller brand

The controller of the machine tool determines the brand of the motor and driver of the rotary table, In case of linkage processing, it is necessary to select the servo that can interact with the controller. In case of single-axis machining, it is necessary to get the electrical diagram.

2. Workpiece's factors

■ Size of workpiece

Because the 5axis platter diameter and rotation range need to be determined according to the size of the workpiece.

■ Workpiece accuracy requirements

When the workpiece tolerance requirement is high, it may be necessary to configure a high-precision encoder to meet the accuracy requirements.

■ Speed and torque requirements

The surface finish and cutting force requirements of the workpiece will affect the selection of the 5-axis, the rotating speed and torque indicators of the table need to be considered.

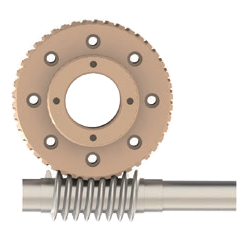

Roller CAM Driver VS Worm Gear

| Item | Roller CAM Driver | Worm Gear Type |

| Appearance |  |  |

| Contact | rolling contact | Slide contact |

| Material | hardening steel ,HRC60 | Hardening steel ,HRC60 |

| Hardness of the contact part | bearing steel ,HRC60 | Phosphor broze,HB90 |

| Preload | YES | NO |

| Transmission efficiency | Good | Worse |

| Backlash | Alway zero-backlash | Necessary for rub strock |

| Indexing accuracy | Under 20 arc-sec | 12-20 arc-sec |

| High speed possiblity | Fast | Slow |

| Flipping time | 0.5sec | 1.5sec |

| Heating possibility | Low | High |

| Rigidity | High | Low |

| Durability | Good | Worse |

| Backlash adustment | Unnecessary | Necessary |

| Expansion of 5th Axis | Yes | No |

| Repair fees | Low(replace needle roller bearings) | High (Replace the worm gear |

| Maintenance costs | Low(do not adust) | High(Adusted once a year) |

Frequent Asked Questions (FAQs)

A 5 Axis Rotary Table is a precision tool that enhances the capabilities of your machining center. It allows movement along five different axes simultaneously, enabling you to machine intricate parts with exceptional accuracy. Unlike traditional setups, this table eliminates the need for multiple repositionings. You can achieve complex cuts and angles in a single operation. This functionality makes it indispensable for industries requiring high precision, such as aerospace and medical device manufacturing.

The core purpose of this table is to provide rotational movement in addition to the standard linear axes of a machine. It integrates seamlessly with your CNC system, giving you full control over the machining process. By using this advanced tool, you can produce parts that meet tight tolerances and demanding specifications.

The 5 Axis Rotary Table consists of several critical components that work together to deliver precise movements. These include:

- Rotary Axis: This component provides rotational movement, allowing you to position the workpiece at various angles.

- Tilting Axis: This axis enables tilting motions, which are essential for machining complex geometries.

- Drive System: High-performance motors and gears ensure smooth and accurate movements across all axes.

- Clamping System: This mechanism secures the workpiece firmly, preventing any unwanted shifts during machining.

- Control Interface: The interface connects the table to your CNC machine, enabling synchronized operations.

Each component plays a vital role in ensuring the table operates efficiently. Together, they allow you to handle challenging machining tasks with ease.

The ability to move along five axes simultaneously revolutionizes the way you approach machining. This movement eliminates the need for manual adjustments, reducing the risk of errors. You can machine parts with intricate designs and tight tolerances without compromising quality.

The 5 Axis Rotary Table also improves surface finishes by allowing the cutting tool to maintain optimal contact with the workpiece. This reduces tool wear and minimizes the need for post-processing. Additionally, the synchronized movements enhance efficiency, enabling you to complete projects faster while maintaining precision.

By incorporating this technology, you gain the ability to produce complex parts that would be impossible with traditional methods. It transforms your machining process, making it more accurate, efficient, and versatile.

- Improved Precision: Simultaneous movement along multiple axes ensures tighter tolerances and reduces human error.

- Reduced Setup Time: Machining complex parts in a single operation eliminates the need for multiple setups.

- Ability to Machine Complex Geometries: Handles intricate shapes, undercuts, and curved surfaces without additional tools.

- Cost Savings: Fewer setups, reduced waste, and lower energy consumption lead to significant savings.

The main difference between a 4-axis and a 5-axis rotary table is in their capabilities and flexibility. A 4-axis rotary table adds rotational movement to the standard 3-axis system, allowing for the rotation of cylindrical or symmetrical parts. However, it still requires multiple setups for complex parts or intricate features.

In contrast, a 5-axis rotary table offers both rotational and tilting movements, providing access to almost any angle of the workpiece. This capability enables it to machine complex geometries, undercuts, and angled surfaces that a 4-axis system cannot. A 5-axis table reduces setup time and improves precision by maintaining optimal tool contact with the material during machining. It’s more efficient for high-precision applications in industries like aerospace and medical manufacturing.