4 Axis Rotary Table

High Quality 4th Axis Rotary Table - Custom Avaliable at SILVERCNC

Looking for a 4 axis rotary table to improve CNC machining efficiency and increase the flexibility of your machine tool?

SilverCNC provide the most cost-effective solution.

Our innovative structural design, high rigidity YRT bearings, and strong braking force ensure stability and wear resistance, while also being maintenance-free Choose.

1. Versatile models compatible with nearly all types of machine tools, such as Haas, DMG, Mazak and more

2. Roller cam structure, maintains precision for 5 years, maintenance-free

3. Customize your 4-Axis simultaneous machine tool with SilverCNC

4. Achieve top precision with encoders from SilverCNC

Best 4th axis CNC rotary table From China Manufacturer

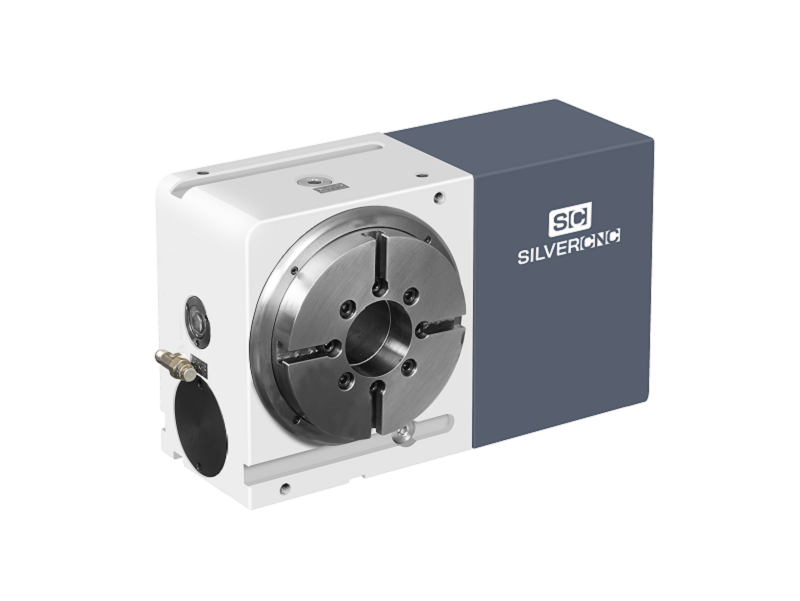

The SilverCNC C Series 4th Axis Rotary Table features advanced zero backlash roller cam drive technology, ensuring high precision, rigidity, and stable performance for extended service life. Its compact design offers efficiency without sacrificing strength, while the sheet metal construction with hidden screws gives it a sleek, modern appearance. The rotary table stands out for its combination of high quality and competitive pricing, giving it an edge over Taiwanese and Japanese brands.

4 axis rotary table Series From SILVERCNC

SilverCNC’s 4-axis rotary table models are named after the diameter of their rotary platters. The diameters range from 120mm to 400mm, with center heights ranging from 110mm to 255mm. Customization of larger rotary tables is available upon request.

Download Specifications and Technical of 4 Axis Rotary Table

How does 4 axis CNC rotary table work?

Transmission Mechanism - Roller Gear Cam

What is CNC roller cam rotary table?

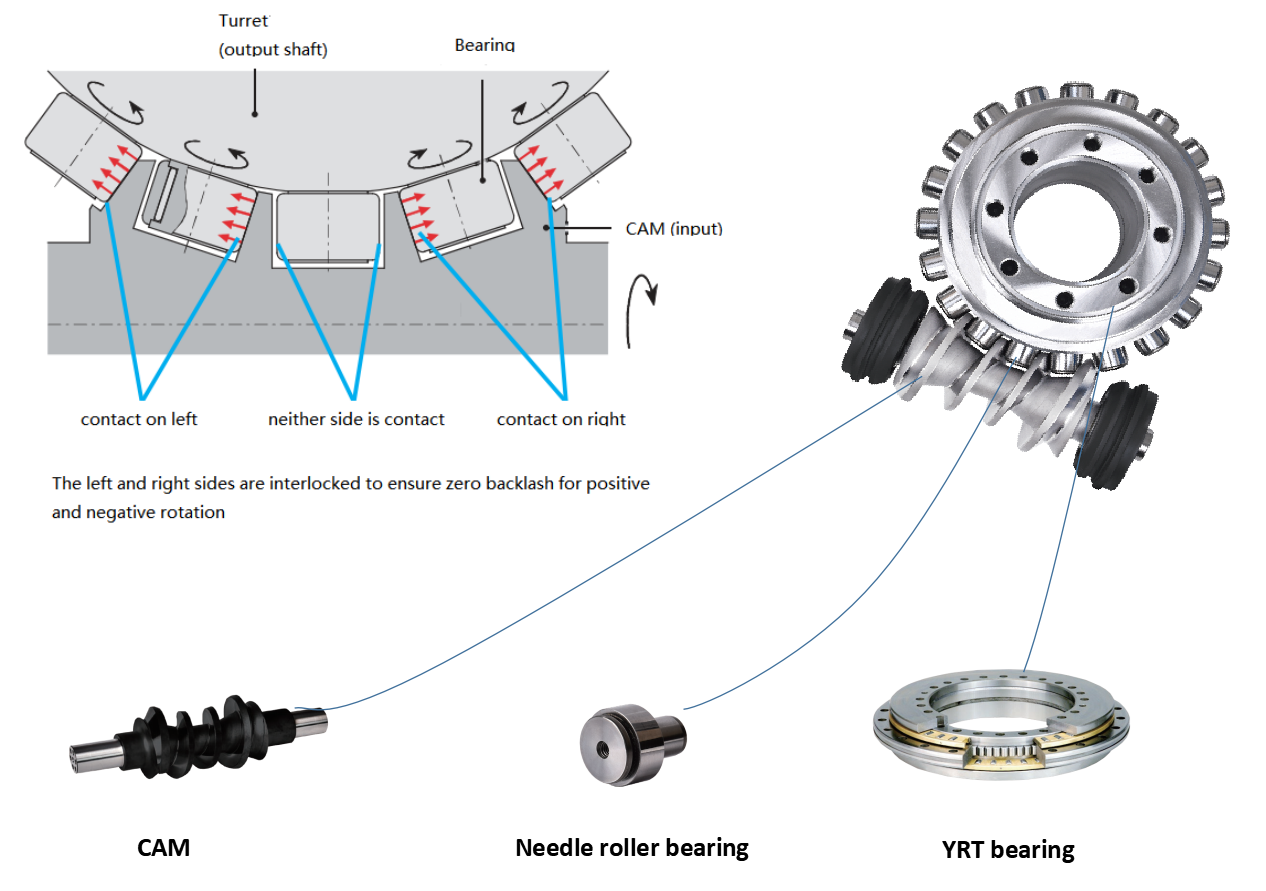

Silvercnc adopts the roller CAM mechanism , one of the finest motion control mechanisms available. The unit is constructed from an input shaft(the roller gearcam) and a turret(output shaft) fitted with roller followers.The roller followers are preloaded against a screw-like input shaft to completely eliminate backlash. Our proprietary adjustment mechanism provides optimum preload. The roller followers planted in the turret use internal roller bearings to transfer torque while rotating. This ensures zero backlash, outstanding precision,and excellent efficiency without causing wear, while providing long-term consistent accuracy, it’s principle below:

Roller CAM 4 Axis Rotary Table Advantages:

Zero Backlash:

The roller cam design eliminates both forward and reverse backlash, significantly improving precision. This innovation enhances the rotary table’s ultra-precision characteristics, reducing defects and elevating machining quality.

Low Maintenance:

With minimal wear and aging, the roller gear cam mechanism maintains its initial precision for extended periods, reducing the need for frequent maintenance.

High Conduction Efficiency:

The rolling contact of the roller cam system ensures minimal friction, resulting in exceptional conduction efficiency. This leads to high-speed operation with a conduction efficiency exceeding 90%.

Extended Service Life:

The rolling conduction mode reduces wear, contributing to a longer service life for the rotary table, making it a cost-effective solution over time.

No Thermal Displacement:

Even during high-speed operations, the roller CAM system minimizes friction and heat buildup, preventing thermal displacement. This enhances stability and reduces defects, ensuring consistent quality.

Superior Brake Performance: When the rotary table is positioned and braked, the disc surface remains steady, with minimal side-to-side movement. This ensures precise braking within 2μm, maintaining exceptional machining quality.

Related Rotary Table And Its Acceorries

Frequent Asked Questions (FAQs)

There are several steps to confirm and choose a right 4 axis rotary table :

(1) Comfirm your machine tool table size to determine the rotary table spec.

(2) Confirm the control system and model of your machine tools to determine what servo motor should equipped.

(3)Confirm the wiring , prepared by our company standard way or provided by the customer

(4)Confirm the braking way, select pneumatic braking or hydraulic braking

(5)Confirm the standard accessories, such as tailstock, base board ,mid-board, hydraulic station and so on

(6)Confirm the color and logo , standard color and logo or customize

The indexing precision of SilverCNC’s 4 axis rotary table is likely in the range of:

- ±20 seconds

- ±25 seconds

- ±40 seconds

This means that the table can deviate by these amounts when indexing or rotating to a specific angle. The ±20 seconds tolerance offers a high degree of precision, typically suitable for tasks like CNC milling, drilling, or other operations requiring accurate positioning.