4 different mechanism of rotary table

At present, CNC rotary table mainly includes four kinds of structure that cam roller, worm gear, DD and harmonic structure. The following is the introduction

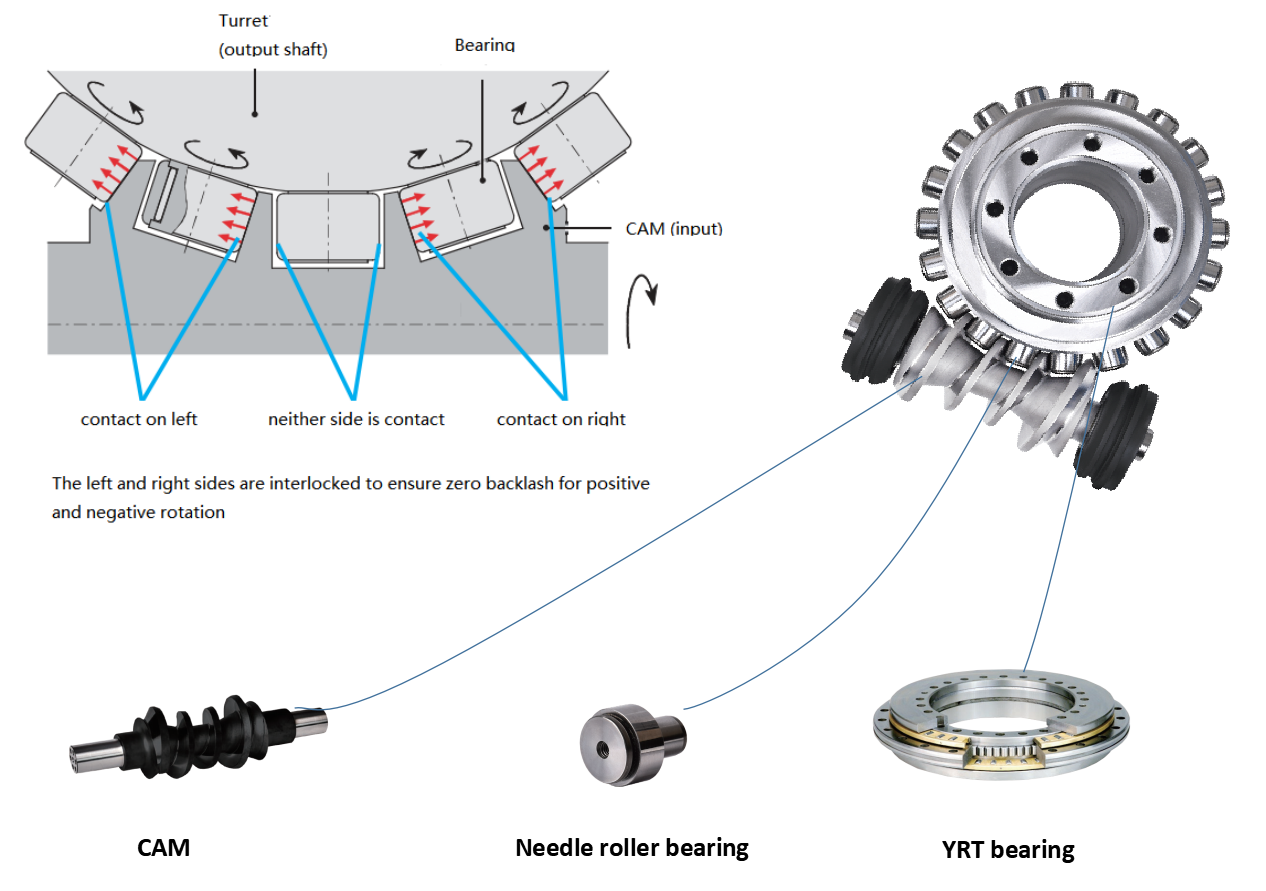

(1) roller cam structure

SILVERCNC rotary table adopt roller cam indexing zero clearance drive technology, which has incomparable advantages over other mechanism rotary tables.

The arc surface indexing principle applied in cam roller drive is the most accurate motion control mode at present. The work piece is composed of an input shaft (arc surface indexing cam) and a roller (output shaft). The cam surface on the input shaft is in linear contact engagement with the outer ring surface of the driven roller element on the roller, so as to drive the runner (i.e. worktable) to rotate. The driven roller element uses an internal roller bearing to transmit torque during rotation. This ensures zero backlash, excellent working accuracy and efficiency, effectively avoids internal parts loss and provides a lasting high-precision working state.

characteristic

Zero backlash structure → achieve accurate positioning and higher accuracy

Roller and cam rolling transfer → fast positioning, higher efficiency, and minimize invalid positioning time

Preloading design → always maintain zero back clearance and maintenance free

The contact surface between roller and cam is large → the rigidity is higher than that of worm gear structure rotary table。

(2) Rotary table with worm gear structure

The two shafts of worm gear drive are crossed and perpendicular to each other; The worm can be seen as a spiral with one tooth (single head) or several teeth (multiple heads) wound along the spiral line on the cylinder. The worm gear is like a helical gear, but its teeth are wrapped around the worm. During meshing, once the worm rotates, it drives the worm gear to rotate one (single head worm) or several teeth (multi head worm). The turbine is made of phosphor bronze, which can not be preloaded and has poor rigidity. With the use and wear, the accuracy of the rotary table decline, resulting in extremely high later maintenance cost, which brings many troubles and economic losses to machine tool users and agents. In order to avoid the shortcomings of worm gear structure, the materials of worm gear need special treatment (such as NIKKEN, Lehman and other high-end brands), but the price is expensive and customers can’t afford it.

(3)DD structure rotary table

DD structure is that the torque motor directly drives the table. The strong torque of the product enables it to be directly connected with the moving device, thus eliminating the connecting mechanisms such as reducer, gearbox and pulley. Generally, this type of motor is equipped with a high-resolution encoder, so that the table can achieve a level of accuracy higher than the ordinary servo. In addition, due to the direct connection mode, the positioning error caused by the mechanical structure is reduced, and the process accuracy is guaranteed. On the other hand, for some camshaft control modes, on the one hand, the dimensional error caused by mechanical structure friction is reduced, on the other hand, the noise during installation and use is also greatly reduced. However, heating is always an unsolved problem for motor direct drive rotary table. Motor heating will lead to bearing deformation, resulting in axis offset, flatness reduction and poor machining accuracy. In addition, the torque of the direct drive motor is small, resulting in poor rigidity, which is suitable for machining and has a small selection range of work pieces. In recent years, the hot mobile phone industry also has very high requirements for DD table. When we make mobile phones, we need a touch probe. The probe transmission signal through infrared. DD table will interfere with the signal because of the current. At present, only FANUC can solve this interference problem, but the price is high, which is difficult for most downstream NC machine tool users in 3C industry to bear.

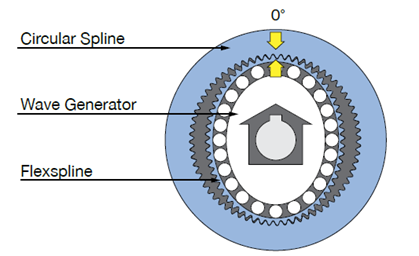

(4)harmonic structure rotary table

Harmonic reducer is a kind of wave generator composed of fixed internal tooth rigid wheel, flexible wheel and radial deformation of flexible wheel. Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design. The lubricating grease in the harmonic reducer can not replace the lubricating oil as easily as the cam roller rotary table, so it is easy to cause wear. The internal flexible wheel of harmonic reducer can not bear large torque, so it can only be used for small and light cutting work pieces.