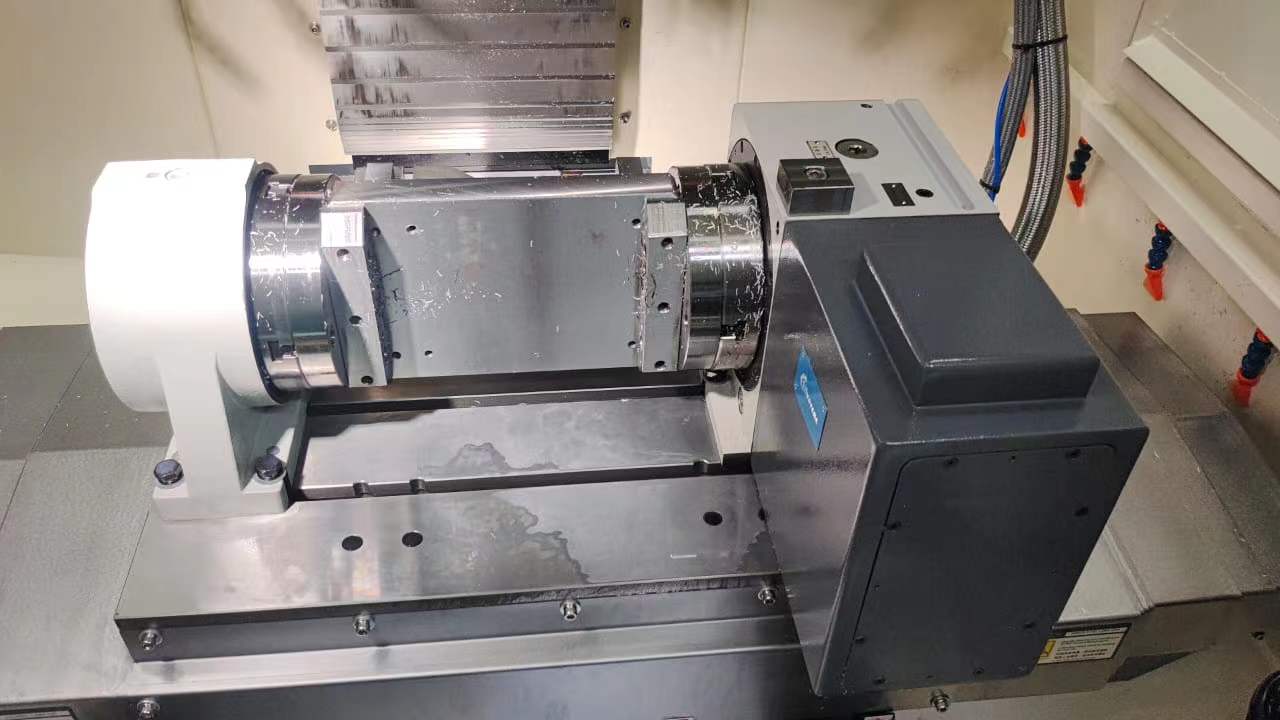

CNC rotary table brake system

Brakes are often used in NC rotary table machining products. Oil pressure / air pressure brakes and servo motor brakes are the two main methods.

The following describes are the control ways and precautions.

Because the silvercnc CNC rotary table is a roller cam structure and adopts no clearance and preload technology, it does not need to eliminate the clearance through braking. This technology reduces the time of clamping and releasing the brake, and can quickly lock the position. However, in order to increase the holding torque of the stop position of the rotary table. We can provide oil pressure / air pressure brake configuration according to the holding force requirements of customers’s. (optional items for customers).

Note: how to select the correct control method is related to the customer’s machine tool characteristics and the customer’s actual use conditions. The following contents are for reference only.

Rotary table brake with pneumatic / hydraulic

| purpose | As the holding brake when the NC rotary table position |

| Recommended method | After confirming the servo motor of the NC rotary table rotates to a specified position, it send the rotation completion signal to the machine tool. the machine tool send the braking command to the NC rotary table, and confirm the pressure with the pressure sensor in the NC rotary table. If the pressure of the pressure sensor is within the range, the braking is completed, otherwise, there is alarm signal. |

| Using servo motor | Two control methods of servo motor are recommended. 1. When the servo mechanism is on continuously, change the proportional integral control to proportional control. This can control the abnormality caused by overload. 2. When the servo motor is a relative value, the coordinates of the servo motor will be lost when the servo mechanism is off. Therefore, when the servo mechanism is off, the servo motor is an absolute value specification, and the action command also needs to adopt the absolute value command. |

| attention | Since “oil pressure / air pressure on → clamping, oil pressure / air pressure on → loosening” is adopted Therefore, when the power supply is off or the oil pressure power source is off, it cannot be clamped |

Rotary table brake with motor

| purpose | As the holding brake of the stop position of the rotary table when the power supply is off or the servo mechanism is off |

| Recommended method | Let the servo drive or upper computer link with the on / off signal of the motor servo mechanism to make the motor brake on / off. After a certain period of time, it is considered that the brake action is completed |

| attention | In terms of servo motor brake mechanism and function, it can not be used to maintain the stop position of the working disc of the NC rotary table and brake the working disc of the NC rotary table during processing. There is the possibility of affecting the machining accuracy. |