Why You May Need CNC Rotary Table?

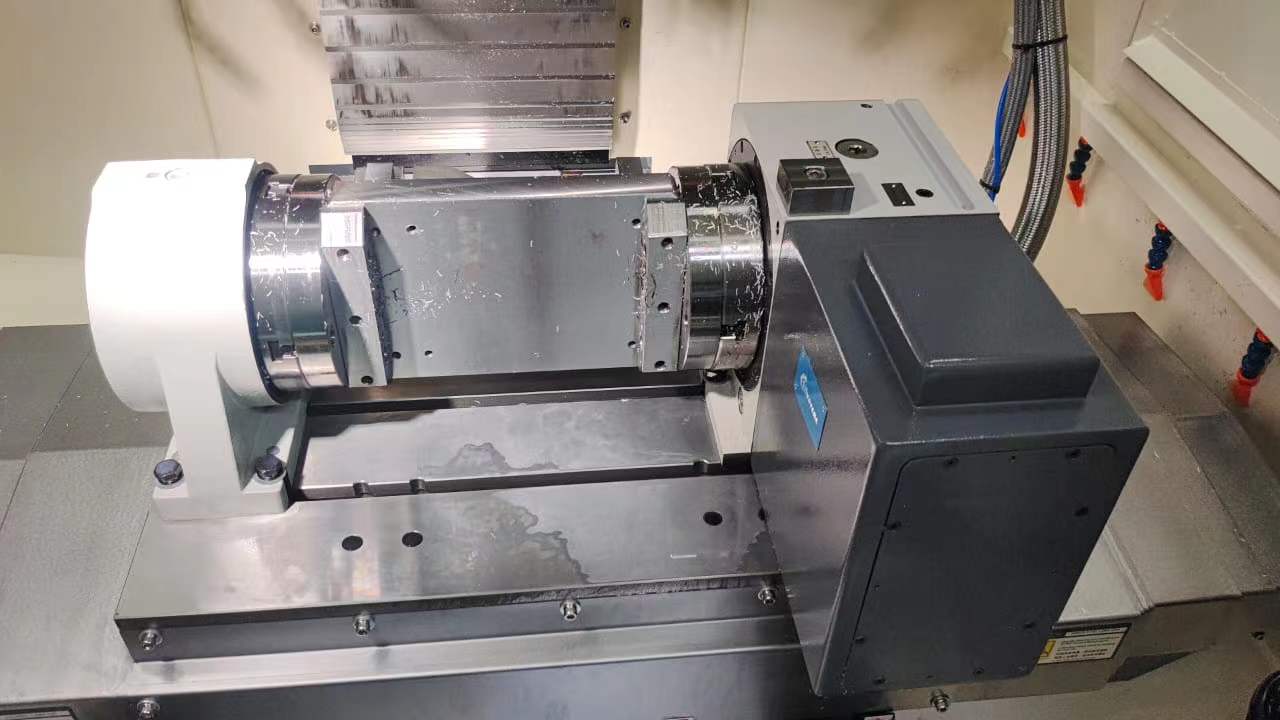

To begin with, a CNC rotary table is a positioning accessory known for its precision. Additionally, it can provide reliable 4 or 5-axis cutting operation capabilities used in a modern-day machine. The best part is that using it will turn the original 3-axis tools into a 5-axis CNC machine. A power rotary table expands the accuracy while decreasing the costs when performing sophisticated machining operations.

What is meant by high-precision positioning in the rotary table?

The feature that comes with a high-precision rotary table is to rotate the piece of work. As such, the cutting tool will create an impressive workpiece accordingly. Besides, a rotary table with high precision abilities can achieve greater accuracy. However, there is a misconception between accuracy and resolution.

For example, if a digital readout has a 4-place decimal place, the rotary table with high precision abilities can achieve accuracy to that value. In addition, to achieve high accuracy, the resolution needs to be higher. Still, it isn’t guaranteed that accuracy should be high.

Accuracy is an idea that represents the difference between the position measured by a device and the actual position. Apart from that, the drive mechanism and the mechanism of feedback like the rotary encoder will have an impact on the overall accuracy of the rotary table.

Benefits of Using CNC Rotary Table

Below listed are some of the benefits of using industrial rotary tables.

1. ADAPTABILITY

Because the metalwork is controlled by the software, the frameworks could be programmed. Later, the same could be adapted by the CNC rotary tables. As a result, it saves a lot of money that would have otherwise incurred when working with large equipment.

It’s the right solution for users who are unlikely to install big machines because they don’t have adequate space to include a variety of drilling and machining applications. So, in terms of adaptability, most users opt for a power rotary table.

2. CONSISTENCY

To gather and machine the workpieces, only programmed instructions through the PC are utilized. The 5-axis operations derived will be more reliable compared to the products that are machined by using several technologies.

Moreover, the setup is straightforward and it provides a unique process for every production cycle needed. When it comes to consistency and quality of metal products, there is no doubt that. The rotary table ensures precision cutting under critical control circumstances.

3. SAVES TIME

Time-saving is another important advantage that you can get from a power rotary table. Apart from the benefits mentioned above, rotational tables help you save a lot of time because of good reasons. The extra finishing and other sub-operation tasks are also done at the same time on the machine effortlessly.

4. MAKES COMPLEX PARTS

Another remarkable benefit of the rotary table is that extreme movements could be completed faster and more precisely. Besides, there are many operation angles, favorable positions, and accessible machining that you can achieve through this intuitive technology.

Hence, the complicated operations are favorable for helical grooves production. Other applications could require adding complex features and require other critical inspections when it comes to the machining process such as manufacturing scientific equipment, automotive parts, and aerospace.

A Variety of Applications

A CNC rotary table is used in several applications including manufacturing, inspection, and assembly. Separate indicators are used for bottling, manufacturing, and so on. In automated machines, the implementation of rotary tables is widespread. Hence, choosing the right mechanism is crucial for improving efficiency while reducing the cost of the component.

In terms of the development of rotary tables, there are different ways to get mass mobilization. When choosing the best rotary table solution, it should match your needs, and factors such as pushing, elevating, and spinning should be considered.

How Do You Pick The Best Model For Your Specific Application?

If you want smart manufacturing but are not sure what to look for in rotary tables, this section might help you. To get started, you have to determine the snapshot of inactivity. This is overlooked often when measuring a rotary table. Another significant factor is the workpiece size that is rotated.

The rotary table should be big enough to handle massive pieces. If you are looking for a reliable China manufacturer that deals in power rotary tables Silver CNC has innovative solutions for your needs. They are in a prominent position for retail and mechanical organizations that want to keep costs low.