Zero Point Clamping System

Silvercnc Zero point clamping and quick change system,which has been widely used in the Chinese market. Because of good quality and low price, it has been recognized by customers and gradually replacing some European and American brands

- Zero-point clamping systems are essential to save time during setup and for successfully improving machine running time.

- Positioning, changing fast and accurately,keeping machine in low downtime are the problems addressed while clamping fixtures and pallets on the machine table. The organizations can produce huge number of units in same amount of time using this system. the machining time for the workpieces on the machine can be used to set up further pallets outside the machine while the machine is running.

- Due to the requirements of labor cost and efficiency improvement,It has a wide range of applications in many kinds of machine tools and industry

Zero Point Clamping System Overview

Silvercnc provide a complete set of quick clamping solutions to improve the efficiency of machine tools for users,silvercnc product including zero point clamping system, quick change fixture, mechanical zero point system, self centering vise, dovetail fixture and some related accessories

Why Silvercnc zero point clamping system

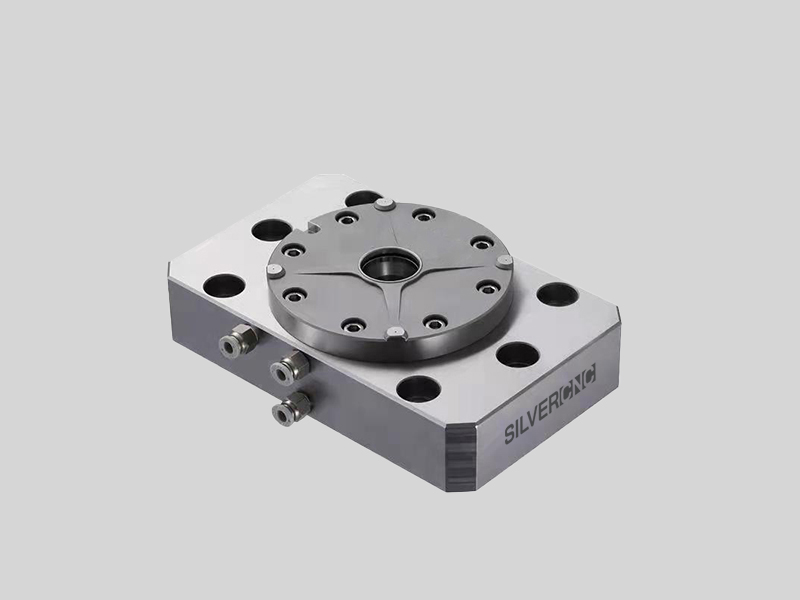

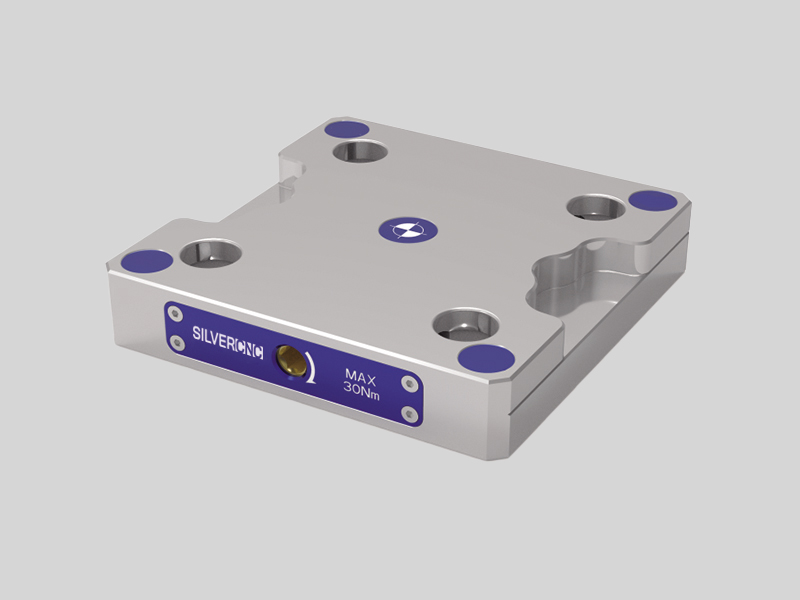

Two different type of designs available

Silvercnc zero point have two structural design, similar to system 3R and AMF respectively, customers can choose according to their own usage habits

Effective, precise, stable zero point clamping system.

The zero positioning of Silvercnc technology adopts proven technology, the product quality is stable. High precision clamping modules with high draw in, locking and holding forces have been widely used by customers in China, with an annual sales volume of more than 5000 sets

Ultra high cost performance

Because of lower labor costs and large manufacturing, the price of products can be greatly reduced. some products price is only half of that of similar European brands

Performance comparison with well-known brands

Brand | System-3R | AMF | EROWA | Schunk | Silvercnc |

Model | S252253 | I20303-1 | ER-133895 | NSE-A3 138-V4-P/ NSE-A3 138 | silver-110107 |

Repeatability(mm) | ≤0.005 | ≤0.005 | ≤0.003 | ≤0.005 | ≤0.005 |

Holding force(N) | 60000 | 40000 | 36000 | 112000 | 60000 |

Releasing(Mpa) | 0.4 | 0.5 | 0.6 | 0.4-0.6 | 0.55-0.75 |

Rust and corrosion prevention | 100% | 100% | 100% | 100% | 100% |

Service life(10000 times) | ≥100 | 100 | ≥50 | 50 | ≥50 |

Automatic chip cleaning | yes | yes | yes | yes | yes |

Automatic cleaning of datum | yes | yes | yes | yes | yes |

Air tightness detection device | yes | yes | yes | yes | yes |

Delivery | 12weeks | 6-8weeks | 8weeks | 8weeks | 3weeks |

Interchange accuracy(mm) | 0.005 | 0.005 | 0.01 | 0.01 | 0.01 |

Sealing | yes | yes | yes | yes | yes |

Price | 1000 euros | 1000 euros | 1000 euros | 1000 euros | 500 euros |

Multiple benefits for using Silvercnc zero point system

Benefits for end user

90%

Reduce setup times by up to 90%

+ 374 h

Additional production time per year

Save money

100000 euros per year for 5000euros cost

Benefits for reseller

More profits

Resell our products will increase the net profit by at least 20%

Logo custom

Silvercnc can customize brands for long-term customers. You only need to be responsible for brand promotion and sales

NO worry quality

After testing the samples, you will be satisfied with the quality

Zero point clamping application

Zero point application video

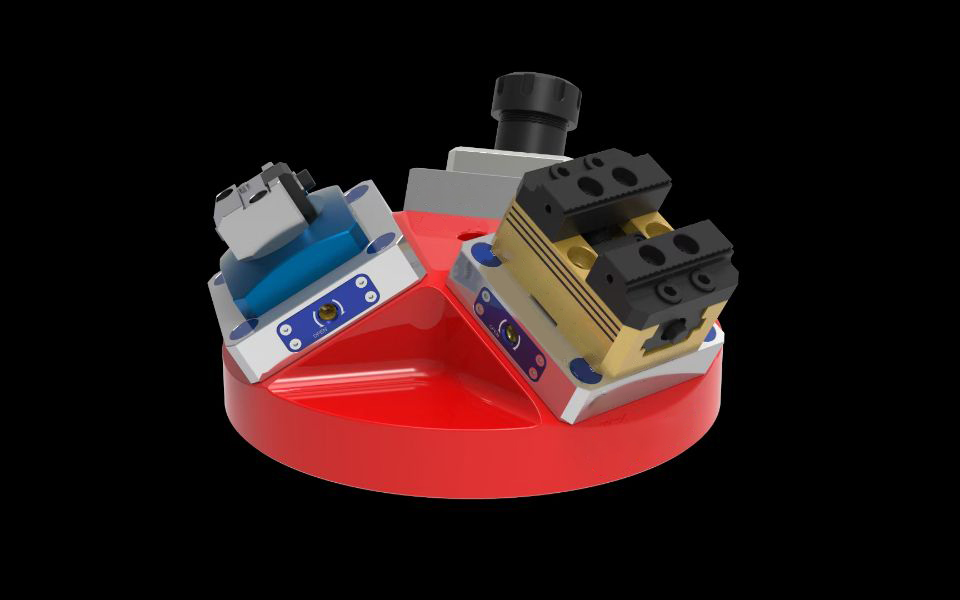

Zero point clamping solution

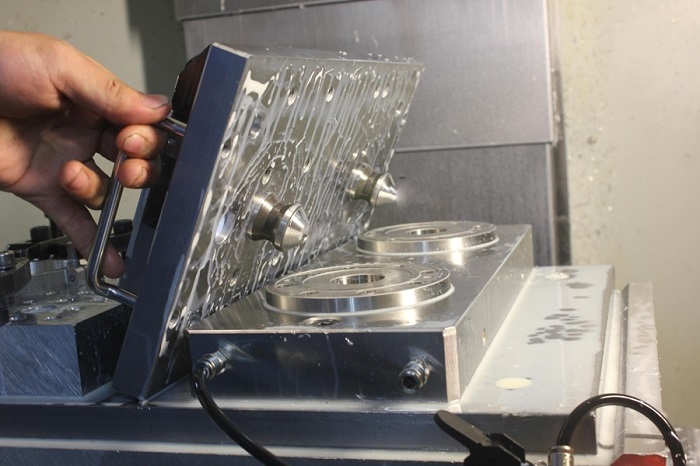

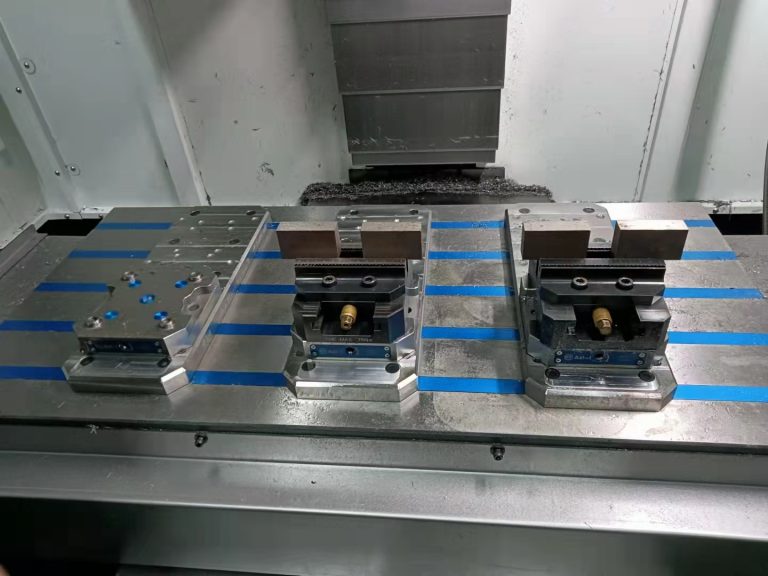

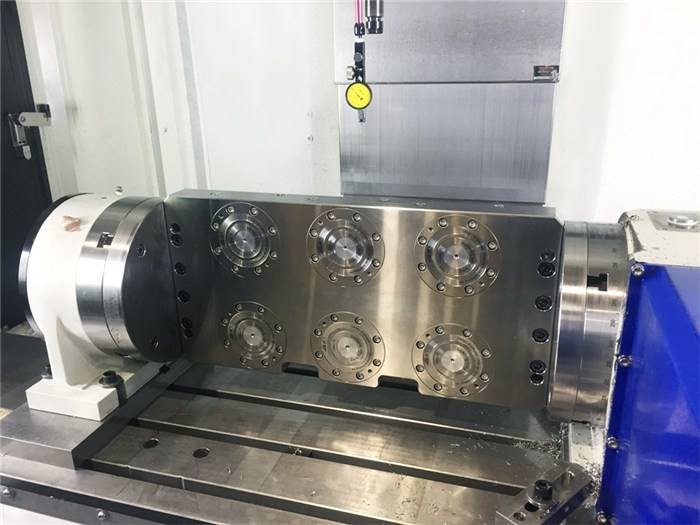

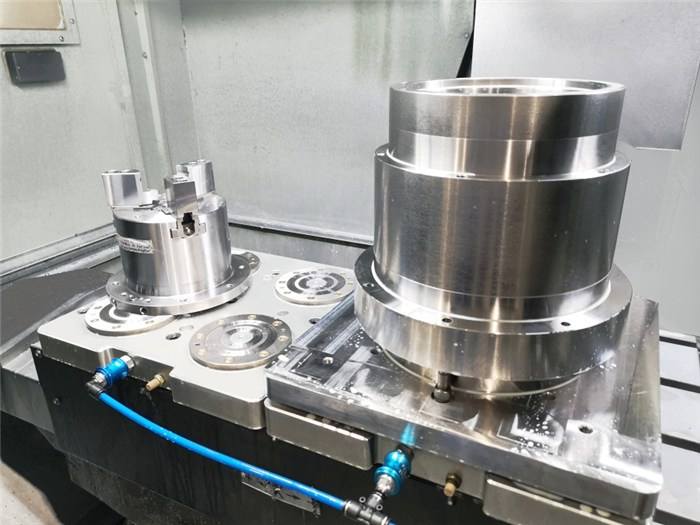

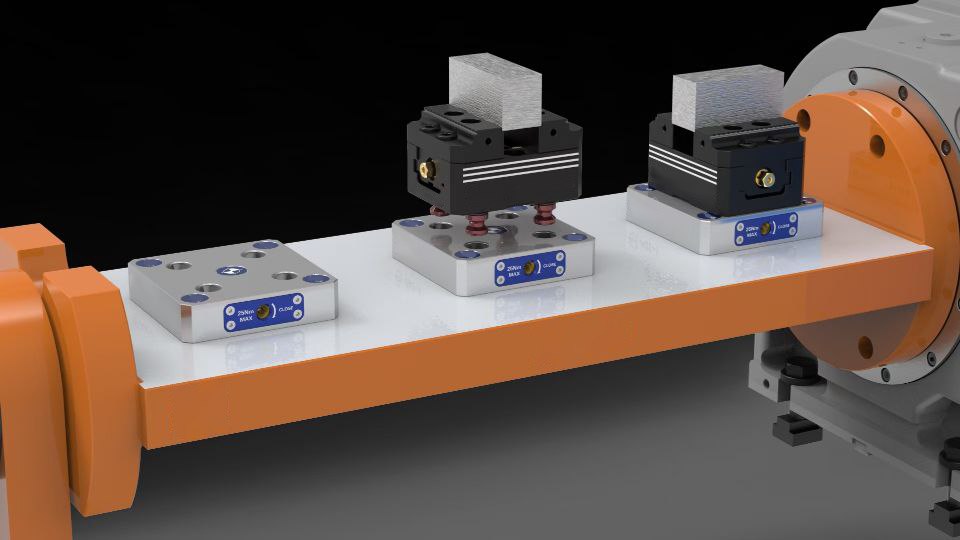

Silvercnc provide a total zero point clamping solution , product include: rotary table,zero point system, self centering vise, dovetail collet, with which can improve the efficiency of your machining center and rotary table. Machining multiple sides of a part becomes possible,operate and replace time decrease substantially,and the accuracy and position accuracy of parts can be better guaranteed

This solution include CNC rotary ,tail stock, mechanical zero point self centering vises.it’s better for smaller machines, smaller parts,and smaller rotary tables. When two vises are installtion together, five side can be machined at one clamping.

The rotary table is equipped with eight self-centering vises, which can machining three faces and 8 parts at one time, and can increase the production capacity by 8 times directly, reduce your machine tool downtime

This solution is a triangle unit. the rotary table add zero point and dovetail jigs which is suitable for machining parts with small size and high position accuracy especially, and allow you to maximize the efficiency of your machine and rotary table

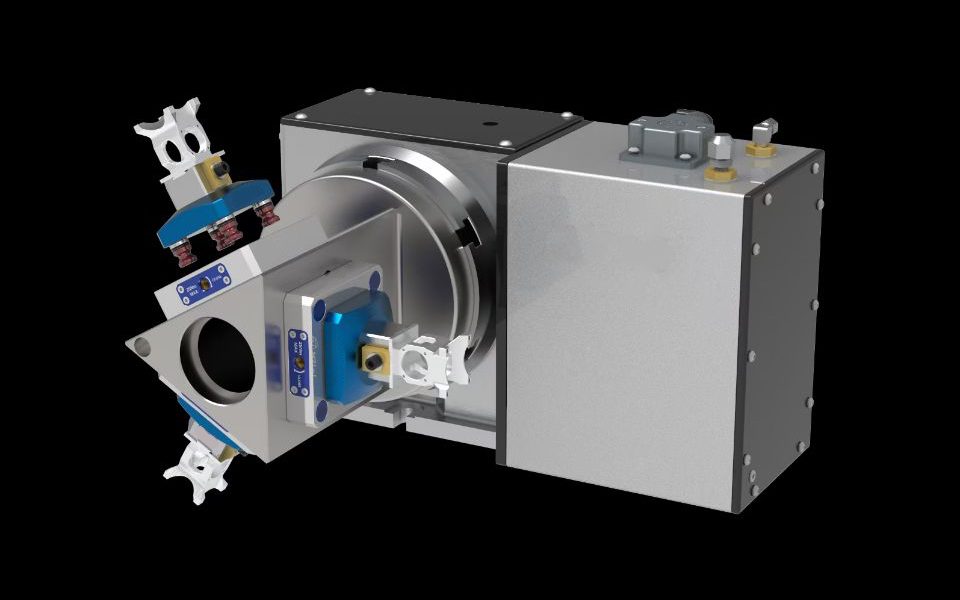

This is a demonstration of clamping way for machining parts of five axis machine tool.you can choose self centring vise, dovetail jigs, zero point, chuck, collect to clamp parts.Maximize the utility of your machine tool’s travel and machining time