Best Quality CNC Workholding Fixtures China Manufacturer & Supplier

SILVERCNC offers a complete set of custom CNC workholding fixtures designed to improve machine tool efficiency for operators. We promise high quality, competitive prices, and fast delivery. Our products are compatible with the 5th axis cnc machining and offer quality comparable to 5th Axis’s products.

- Saving set time and reducing machine tool down time

- Zero point base plate 4-point clamping design, 14kN power clamping force allow heavy machining

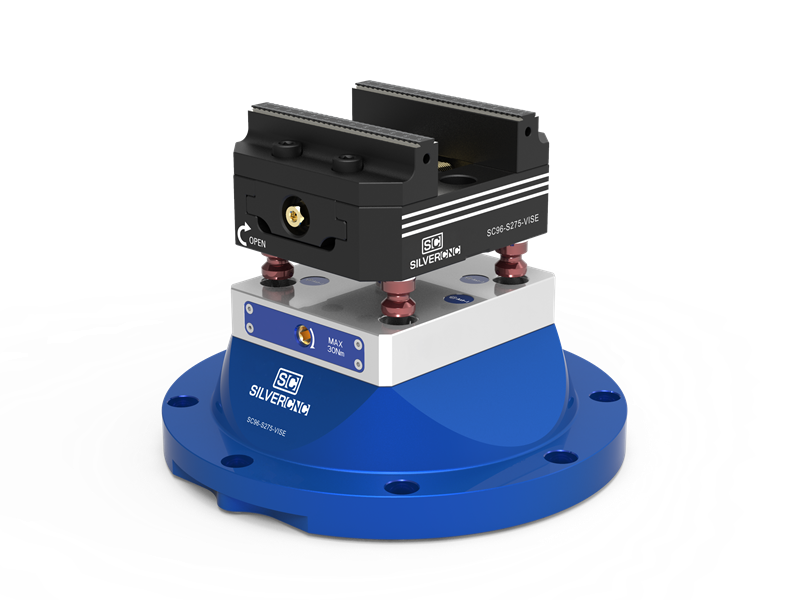

- Sefl centering vise is compact design,high repeatability accuracy and stability

- modular collet and chuck fixture designed for clamping round bar workpiece quickly and effectively

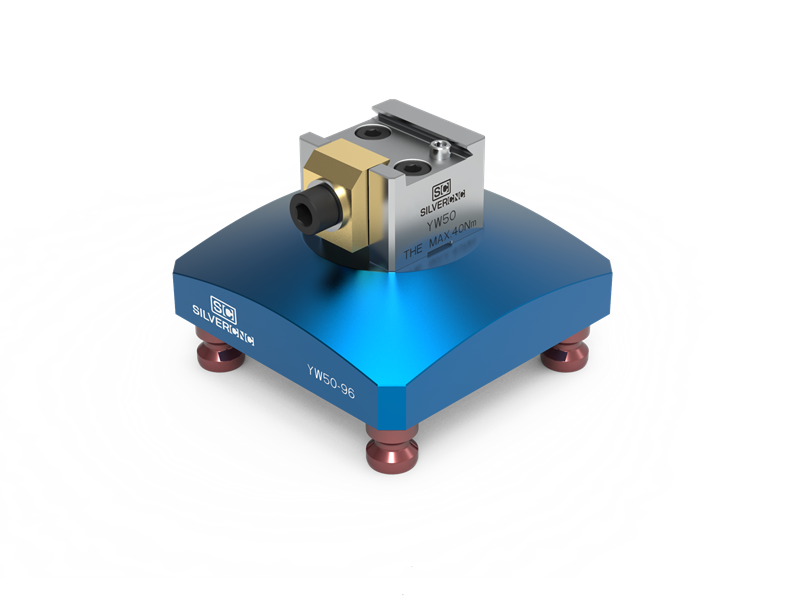

- Mdular dovetail fixture designed to achieve quick change between different part

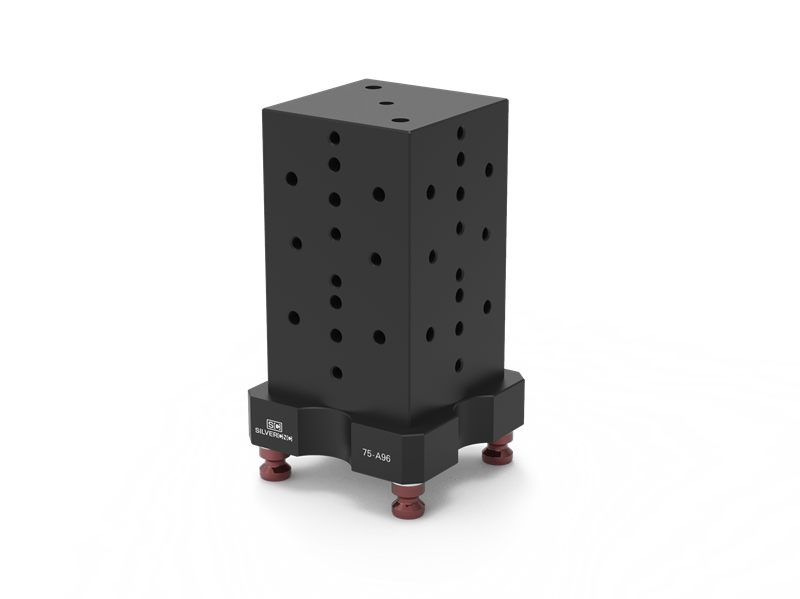

- Riser and pyramid used to increase the productivity of 5 axis machining centres

SILVERCNC CNC Workholding Solutions

Our custom cnc workholding fixtures include :

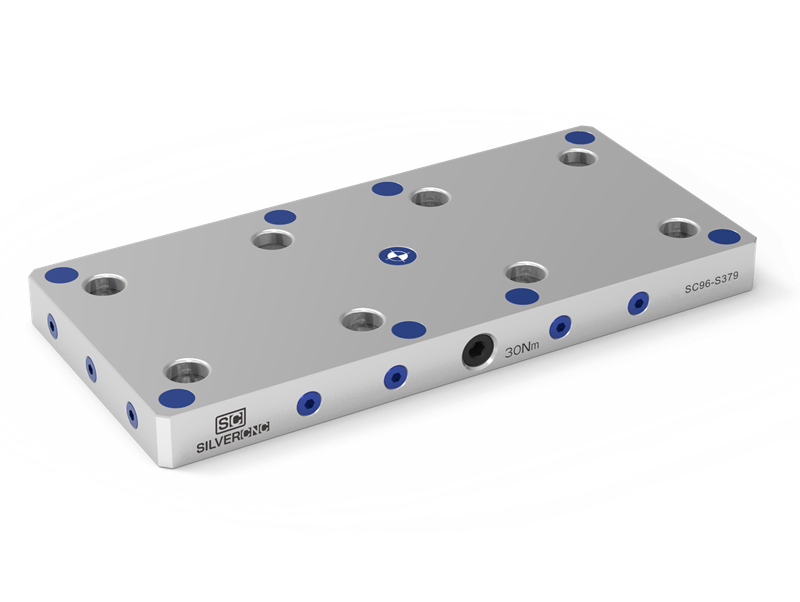

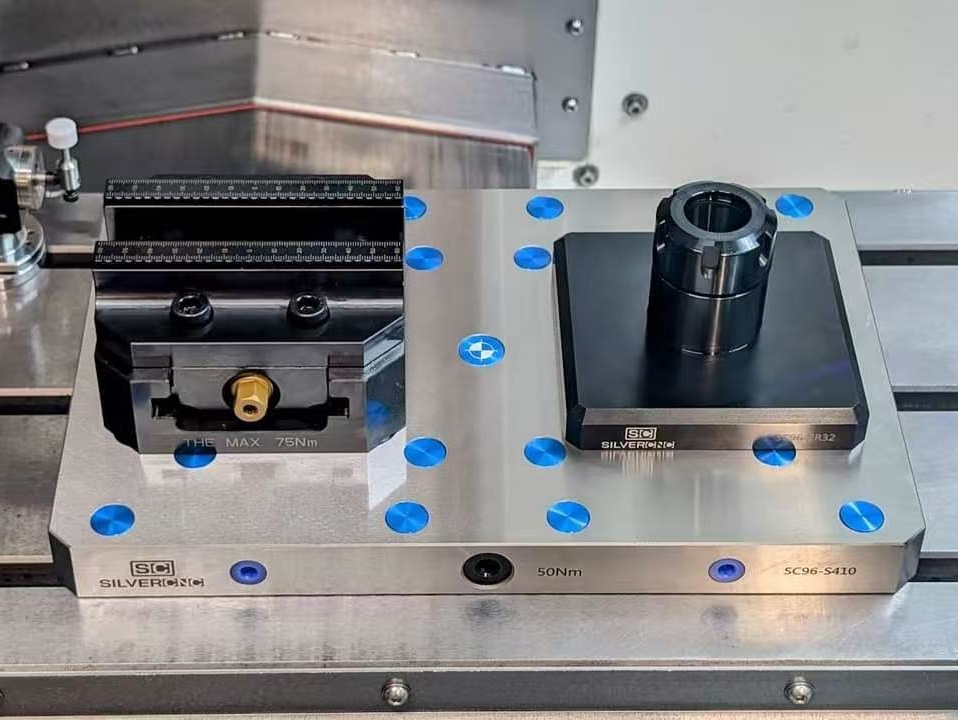

Zero point base plate (52mm and 96mm), Multi -positon base plate, Pneumatic type base plate

Self centering vise, Riser, Pyramid, Tombstone, Dovetail and chuck.

Applications of CNC Workholding Fixtures

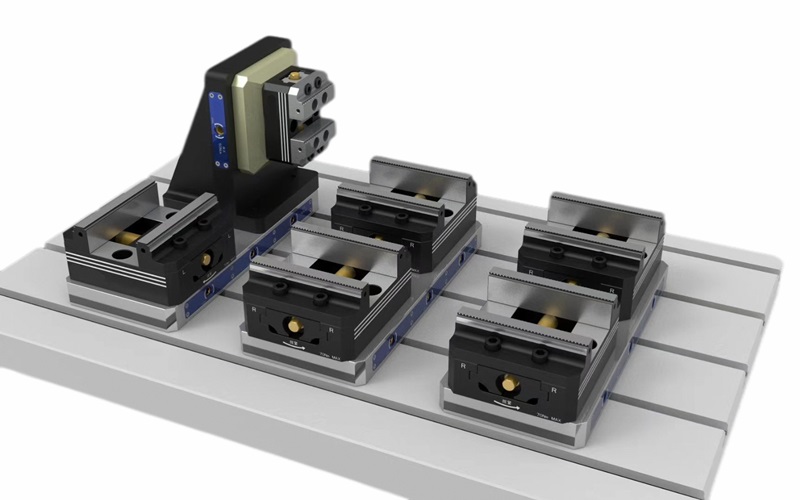

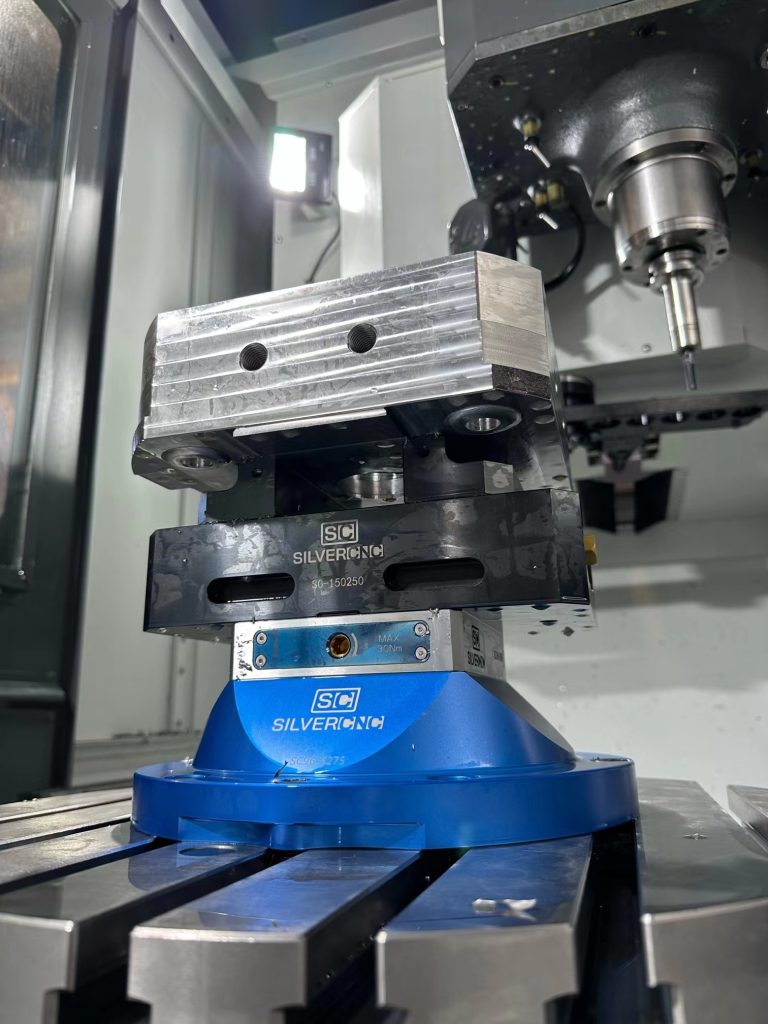

base plate,self-centering vise,angle plate

Zero point base plate and self centering vise fixed on machine tool table are the most commonly used scenarios

Double station plate can improve machine tool usage and clamping efficiency further

Without rotary table, when using a right angle plate, 5 surfaces can be machined to ensure machining accuracy

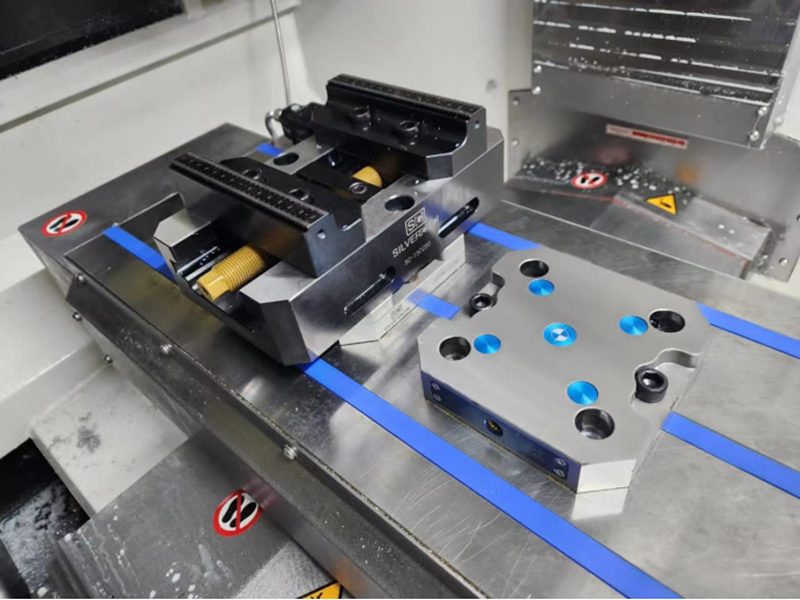

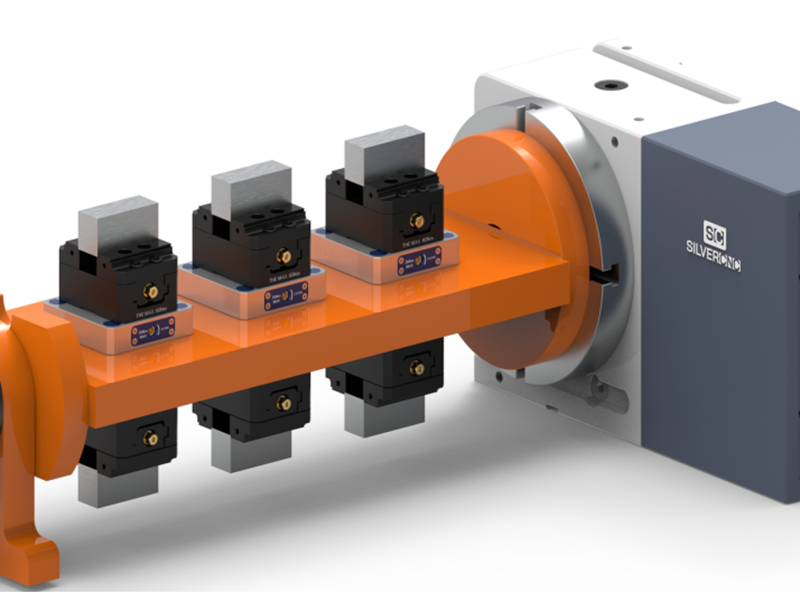

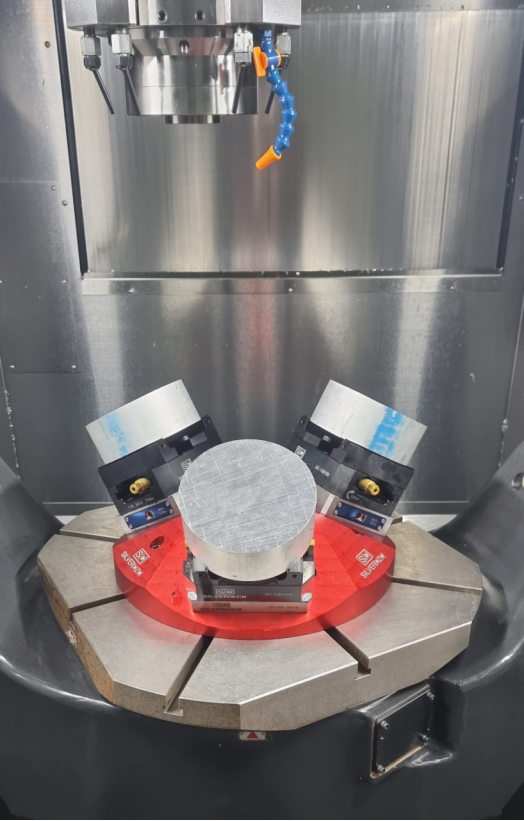

Application - on 4th axis rotary table

Fixing the zero point base plate on the flange of the 4-axis, combined with various types of fixtures to ensure that the coordinate origin remains unchanged, which can achieve efficient clamping and machining

For C170 and small 4axis models, please use 52mm plate, for bigger 4axis models, please choose 96mm type zero plate and self centering vise

please use the positioning hole on the zero plate to calibrate the center without purchasing a center calibration plate

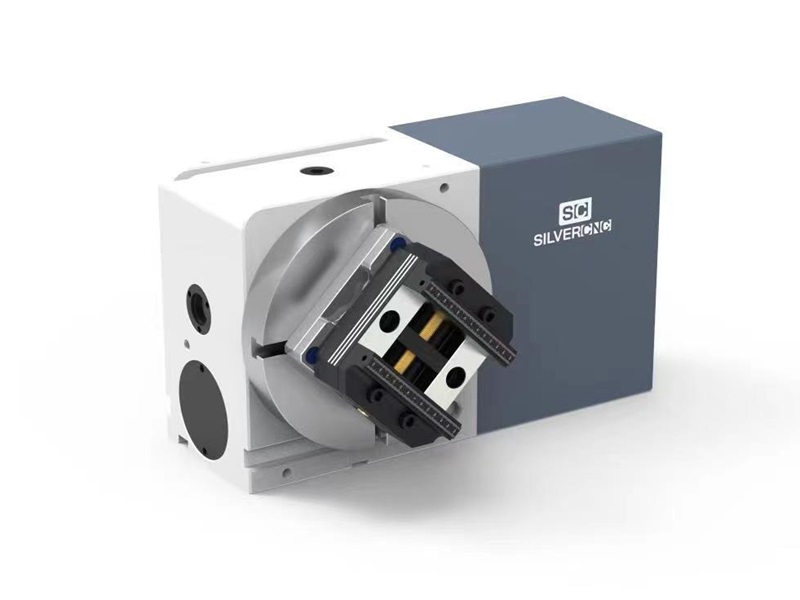

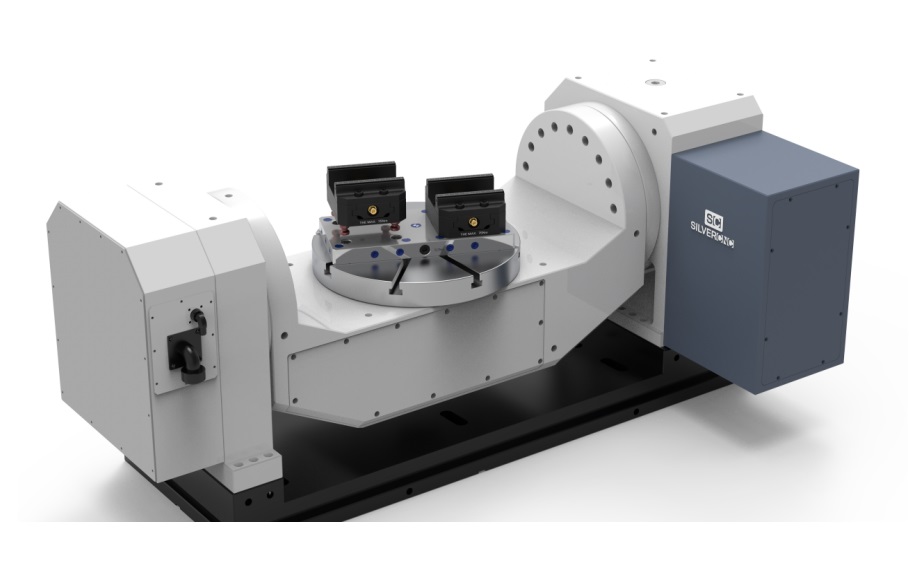

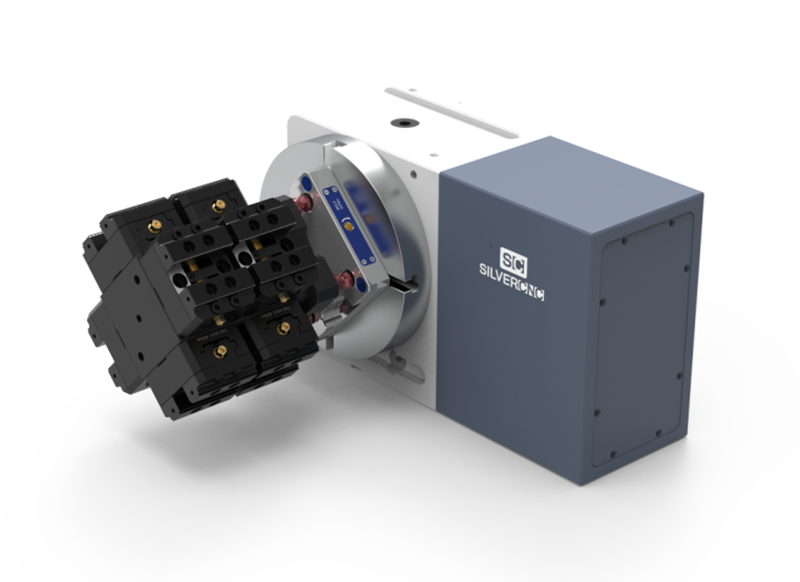

Application - on trunnion table

The trunnion table and zero point plate are also the most common application.

4axis rotary, tailstock, 2/3/4 multiple sides in one bridge plate, 2/3/4 sets of zero point,vise,chuck combination

Pneumatic zero point plate can also be selected to achieve automated upper and lower workpiece for machining.

dovetail fixtures Application

Dovetail fixtures can be mounted on four and five-axis CNC machines for milling applications. It offers superior clamping strength and part access

Dovetail and zero point plate combined, which can reduce clamping time, improve the efficiency of machine tool, and also improve machining accuracy.Ideal for small parts that need a lot of clearance

Three models of dovetails for you to choose.all of which has been improved to have the ability to mount to 52 and 96mm base plates

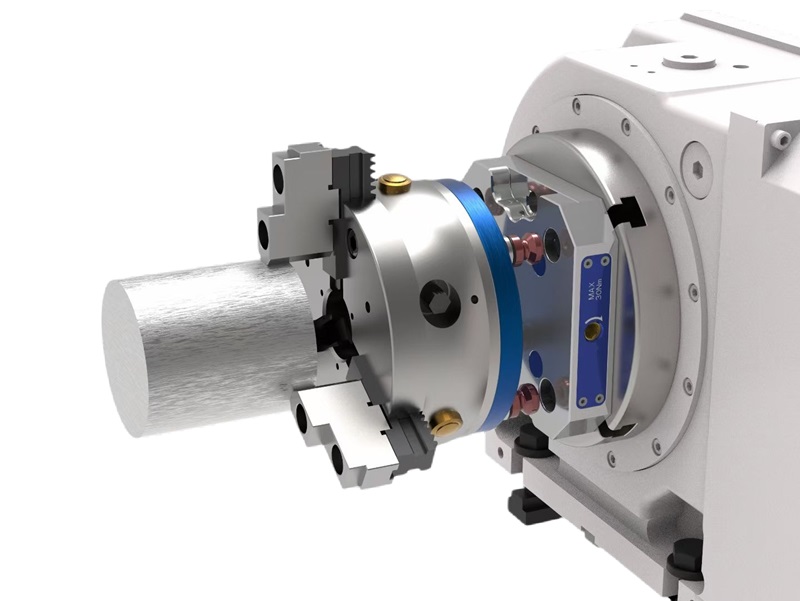

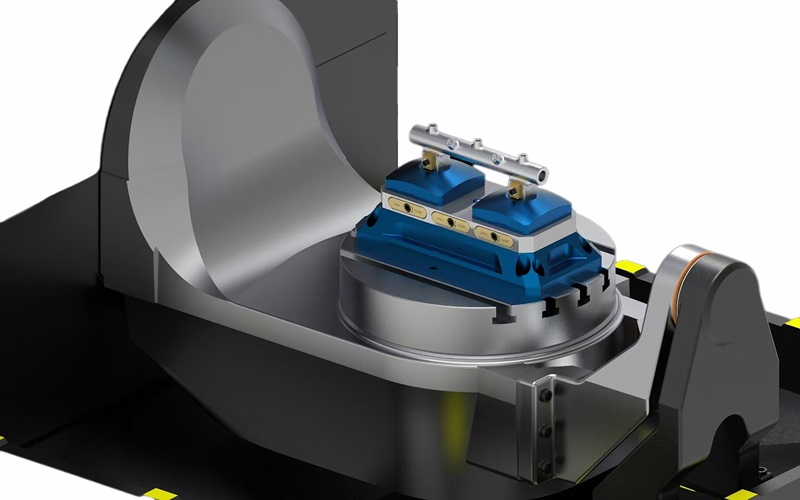

Application - on 5th axis rotary table

The trunnion table and zero point plate are also the most common application.

4axis rotary, tailstock, 2/3/4 multiple sides in one bridge plate, 2/3/4 sets of zero point,vise,chuck combination

Pneumatic zero point plate can also be selected to achieve automated upper and lower workpiece for machining.

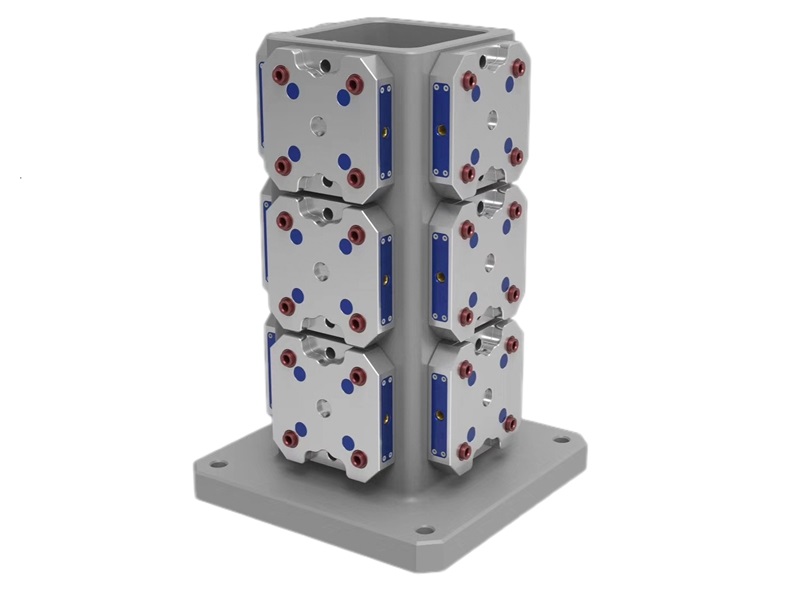

Riser and pyramid application

For some small parts machining on 5axis machine tools, you have to increase the height of the parts to improve flexibility and prevent interference.

Riser and zero point plate is a very popular and cheap solution. The material for the raised is aluminum, and the bolt holes at the bottom are determined based on the machine tool work table T-slot distance.

pyramid design provides maximum access to all machined surfaces and allows or enhanced spindle and cutting tool clearance

SilverCNC pyramid compatible with SC96-S195 zero point plate,various of dovetail,vise, chuck and serrated jaw options are available.

tombstone application

Tombstone used on HMC or rotary table, which is an efficient and effective workholding solutions for CNC machining operations

Many type of fixture can fixed on the tombstone, such as zero point plate, self centering vise, OK vise. to meet your processing requirements.

CNC Tombstome can also be integrated with 5th axis rotary table for processing multiple surfaces at one time, improving machining efficiency.

Why Choose SILVERCNC For Custom CNC Workholding Solutions

SILVERCNC, established in 2014, brings over 10 years of experience in providing CNC workholding fixtures. Our deep industry knowledge helps us design solutions that meet the specific needs of our customers. We are committed to delivering high-quality fixtures that ensure precision and reliability, making your manufacturing process more efficient. Our goal is to help you find the best solutions for your needs, ultimately improving your operations and driving long-term success.

- Custom Solutions: We work with you to design fixtures that fit your specific requirements. This ensures better efficiency.

- High Precision: Our fixtures are made to hold your parts securely and consistently. Our products deliver reliable results.

- High Quality: We use durable materials to make sure our fixtures last. Our products are designed to perform well in tough conditions.

- Quick Turnaround, Fair Prices: We deliver fast. Our prices are competitive, so you get great value.

- Support When You Need It: Our team is here to help. We provide

quick customer support for any questions or concerns.