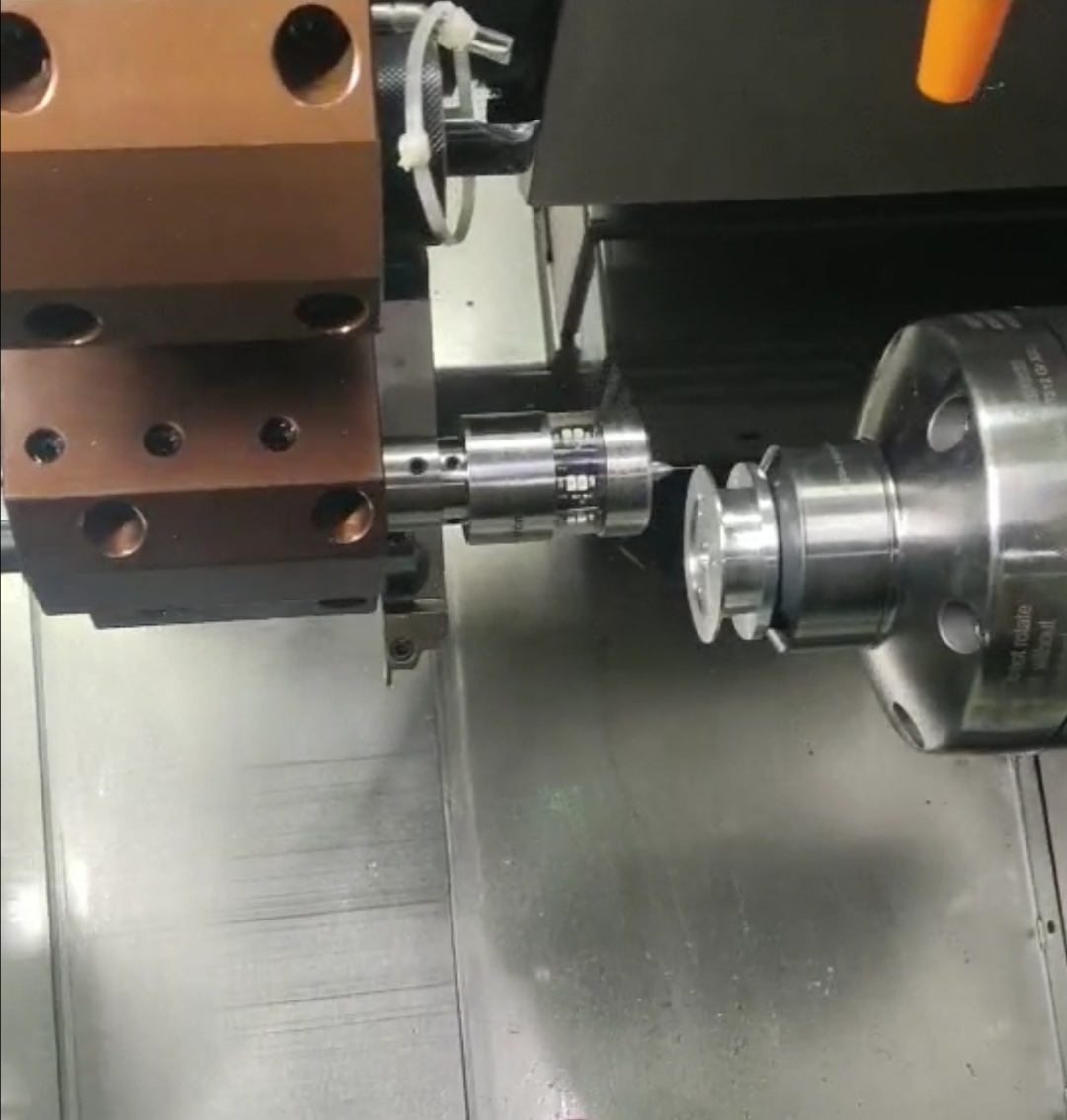

CNC rotary table is a device used to assist the workpiece in multi angle machining on the machining center. One-time clamping and multi-faceted machining can ensure the position accuracy between workpiece features and improve the use efficiency of the machine tool. In contrast, the standard machining center has only three axes x, y and Z. after adding four axes, it can process workpieces with complex features, such as blades, cams, etc.

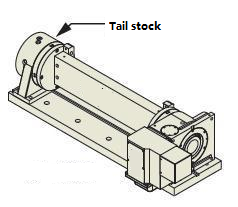

In practical application, it is necessary to match with some additional accessories to meet the requirements, such as disc tail stock, chuck, zero point system, controller mode, braking device, etc

Therefore, before purchasing the rotary table, you must know how to select the correct rotary table and model.

1. Confirm the material of the work piece and the cutting force during machining

If the work piece is made of aluminum, copper materials, and the machining cutting force is small, you can choose harmonic gear, DD motor type rotary table, or choose worm or roller cam structure, and use pneumatic brake.

If the parts are made of cast iron, steel and other materials, it is recommended to select the rotary table with worm or roller cam structure, and judge whether to add hydraulic brake according to the cutting force.

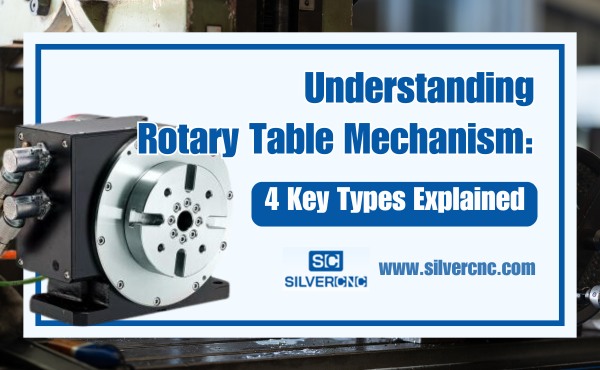

Four different types of rotary tables, please click the link to view our previous articles

2. Confirm the Shape and size of workpiece

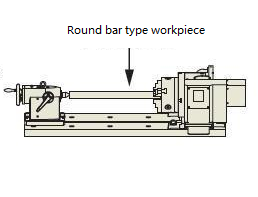

1. If it is round bar type, please purchase three jaw chuck and thimble tailstock. When selecting three jaw chuck, the outer diameter of chuck shall not be greater than the diameter of disc surface,

2. If it is odd and abnormal, and more than 2 workpieces are processed at one time, please purchase additional disc tailstock. In addition, L-shaped block, large base plate and medium plate can be made according to actual needs

※ when using the bridge plate, the width dimension of the bridge plate shall not be greater than the disk diameter

3.confirm the Indexing Accuracy

(1). Worm, roller cam and DD motor rotary tables have different accuracy and retention life.which should be determined according to the workpiece accuracy

(2).If accuracy specified in mm, check for the diameter at which the accuracy is required.Convert Indexing Accuracy of the Rotary Table specified in arcsec to mm at the diameter where the operation is to be carried out,(A = Tan Ө x R),Ө = Indexing Accuracy (Ex: +/- 15” (30”sec)),R = Radius at which the operation to be carried out ,A = Accuracy in μ

(3). Higher accuracy of +/- 5” can be achieved by using an additional encoder mounted on the table axis, but price is high.

4. Confirm the rotary table load and machine tool load

(1) First confirm that the rotary table can bear the load of the workpiece,

(2) Confirm the total load that the machine tool can bear, and then add up the weight of the preselected rotary table, tail stock, L-Block, medium plate (bridge plate), base plate, work piece, fixture and so on,

(3) If it is overweight, judge the material of the workpiece first. If it is aluminum alloy or other light materials,which caused by the long shape support joint or large rotation diameter of the work piece, you can change the indexing disc to a smaller model and add a cushion block to reduce the weight, so that the price is low and can meet the requirements of the rotation diameter of the work piece.

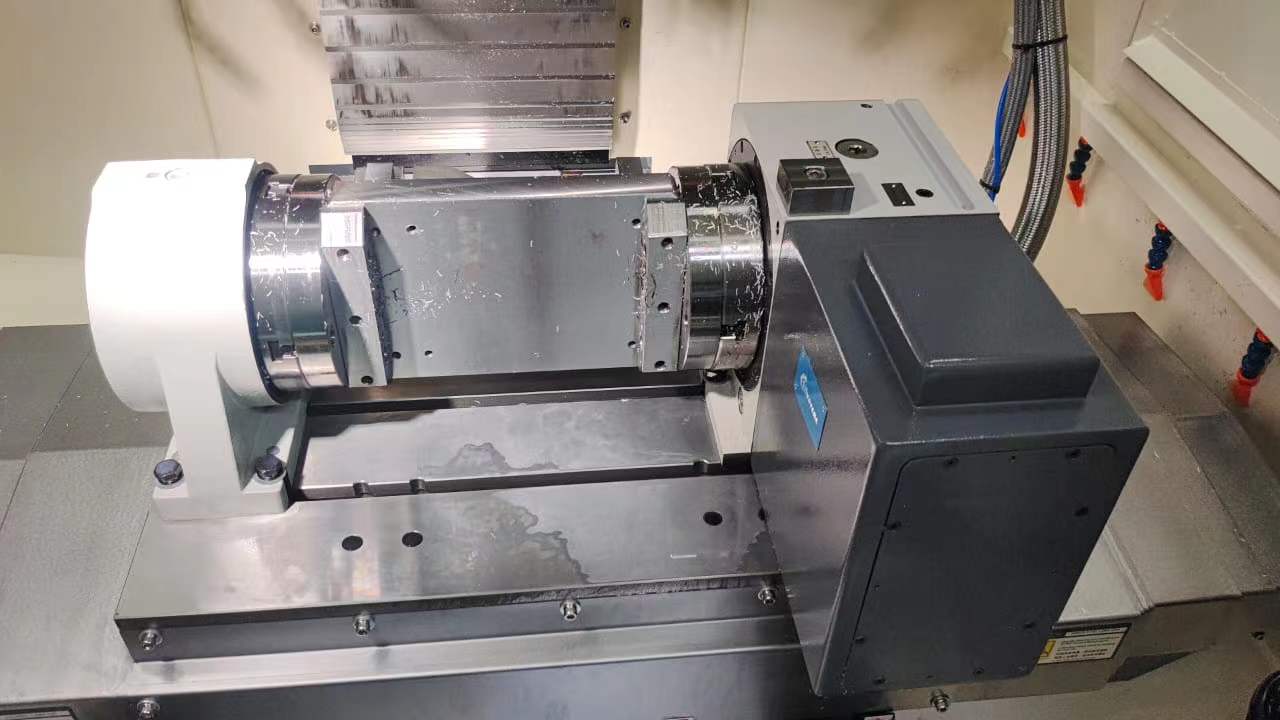

5. Confirm the interference in the y-axis direction

After moving the Y-axis of the machine tool to the origin, measure the distance from the center of the worktable to the metal plate of the moving door of the machine tool, check the size from the center of the disk surface of the indexing plate to the tail end of the motor cover, and judge whether the motor cover will interfere with the metal plate of the machine tool. If there is interference, change the motor cover

6. Confirm the available space for placing work pieces

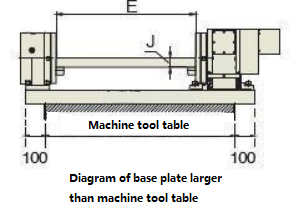

First confirm the length of the machine tool workbench, especially when the scheme of disc tail stock and bridge plate is selected, the bottom plate is 200mm larger than the machine tool workbench at most, that is, 100mm will protrude on both sides, which is the maximum allowable protruding position

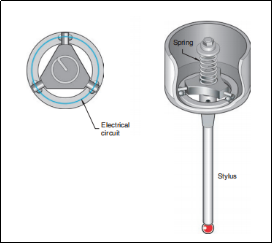

7. Interface between rotary table and machine tool controller

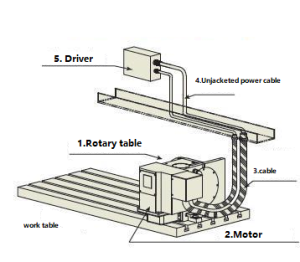

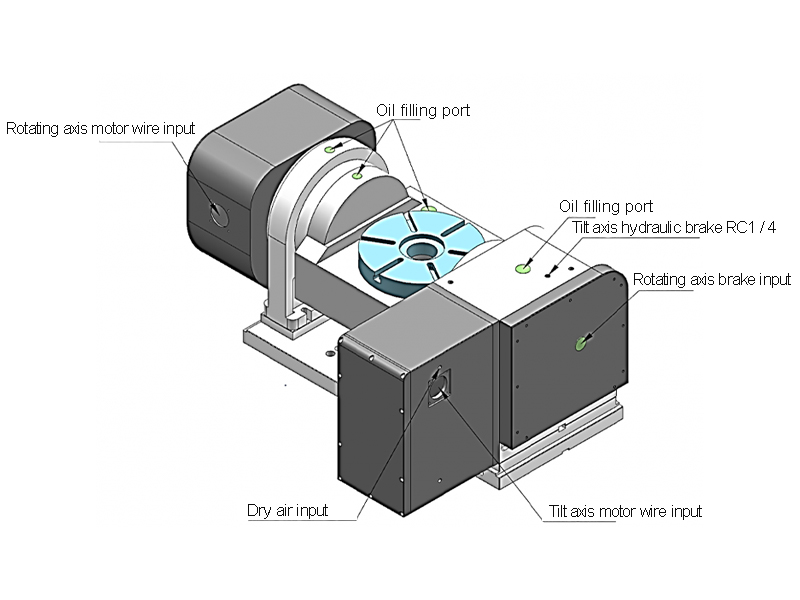

The rotary table is generally composed of several parts as shown in the figure below: ① rotary table house, ② motor of the fourth axis, ③ cable with sheath, ④ cable without sheath, and ⑤ driver. In addition to the five major hardware, the interface must be reserved for the fourth axis on the machine tool.

(1).If the machine tool reserves the interface of the fourth axis, it is possible to add the fourth axis to realize linkage machining

(2).If the machine tool does not have interfaces reserved for the fourth axis, but wants to add the fourth axis later, please ask the machine tool manufacturer to open the interface or select the single axis controller, but the single axis control system cannot be linked with any axis of the X, Y and Z axes of the machine tool. Only after the rotation of the fourth axis is completed, the other three axes can operate.

7. NOTE:

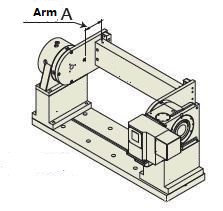

when purchasing rotary table and disc tail stock, and designing the cradle type fixture, when eccentric machining is caused by the force arm (A) exceeding the disc surface (the higher the cushion is, the longer the force arm A is, which is not the load of mechanical common sense), it will seriously wear the rotary table reducer. Please be careful