Daily maintenance of CNC rotary table

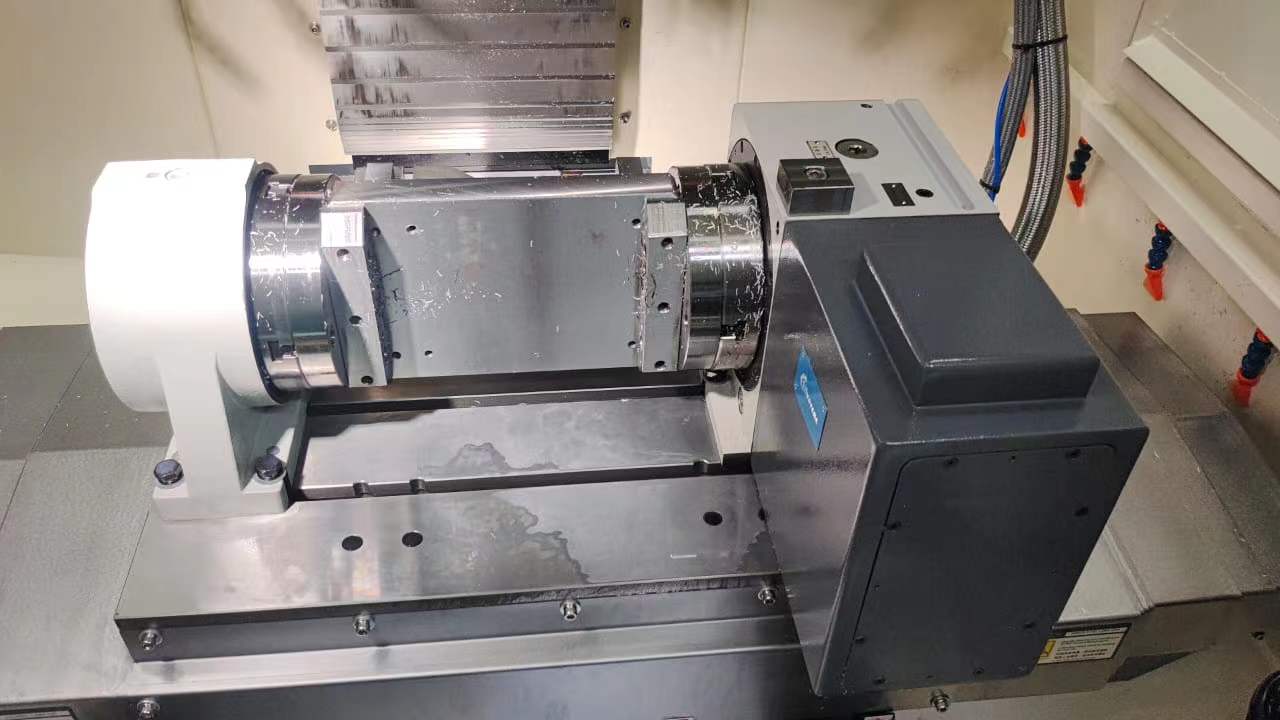

The CNC rotary table produced by Silvercnc technology adopts cam roller structure, which has the advantages of zero clearance, high precision, high efficiency and low maintenance cost. The most used rotary table using worm gear structure on the market adopts phosphor bronze. The back clearance after about half a year requires professional and technical to readjust the accuracy, while the silvercnc rotary table adopts cam roller structure, The cam roller structure is rolling friction. The hardness of the input shaft and output shaft reaches HRC60 degrees, which can be used for 5 million revolutions without change in accuracy . Therefore, the user does not need to adjust the clearance of the rotary table. The daily maintenance is inspection and replacement of lubricating oil.

Lubricating oil plays an extremely important role, such as reducing rotary table wear, removing friction heat, rust prevention, etc. Therefore, poor lubrication may lead to short service life and abnormal heating. Please replace and supplement the lubricating oil regularly according to the following requirements.

Recommended lubricating oil: Mobil SHC629

A. Check the oil mirror regularly

Whether the oil quantity of the main box is sufficient. If it is insufficient, please supplement the appropriate oil quantity.

B.Lubricating oil replacement

The lubricating oil must be replaced at least once a year. When the lubricating oil is found to be deteriorated, please replace the lubricating oil immediately.

(一) lubricating oil replacement method

1.Clean the oil filler, oil drain and the periphery of the oil mirror of the product, and remove chips, impurities, etc.

During refueling, if impurities and other foreign matters are mixed into the product, it will cause failure.

2.Remove the screw of the oil drain hole to drain the lubricating oil and carry out the oil drain operation.

When draining the lubricating oil, if the oil filler is opened at the same time, the oil can be drained faster.

3.Confirm whether the lubricating oil is completely drained.

Remove the sealing tape scraps attached to the oil filler.

After winding the sealing tape to the oil drain plug, plug the oil drain port.

4.Confirm the oil drain holewhetherhas been closed or plugged, and then refuel the lubricating oil.

When adding lubricating oil, the oil level should be controlled just above the upper limit of the center point of the oil mirror.

5.Confirm whether there is leakage of lubricating oil, and wipe the oil spilled on and around the body.

(二) . precautions for lubricating oil replacement

1.It is strictly prohibited to use non designated lubricating oil to avoid shortening service life, aging of components and other consequences.

2.Do not replace or supplement lubricating oil after operation and just after stopping operation.

3.The product body may be in a high temperature state. If it directly contacts the product or discharges oil, it may cause scald. In addition, please note: at this time, the internal lubricating oil temperature is higher than the surface temperature of the product body, and the lubricating oil may be strongly retained and splashed.

4.When the lubricating oil level does not reach the center of the oil mirror, be sure to replenish the lubricating oil.

5.Please dispose of the used lubricating oil discharged from this product according to law.

6.It is forbidden to conduct air purging when the oil drain and oil filler are opened. Otherwise, sand and dust will enter the product and cause failure.

7.Please wear gloves and use brushes and other tools to remove the chips attached to the product. Do not remove debris with empty hands.

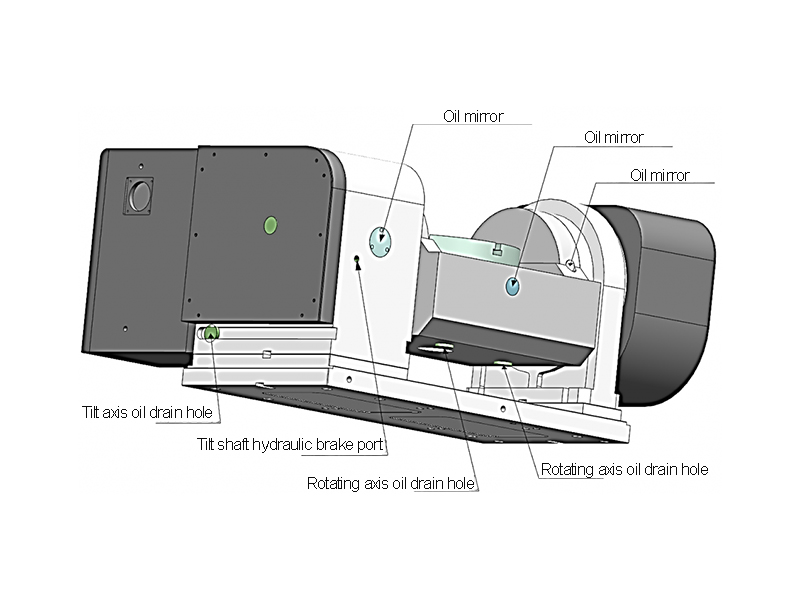

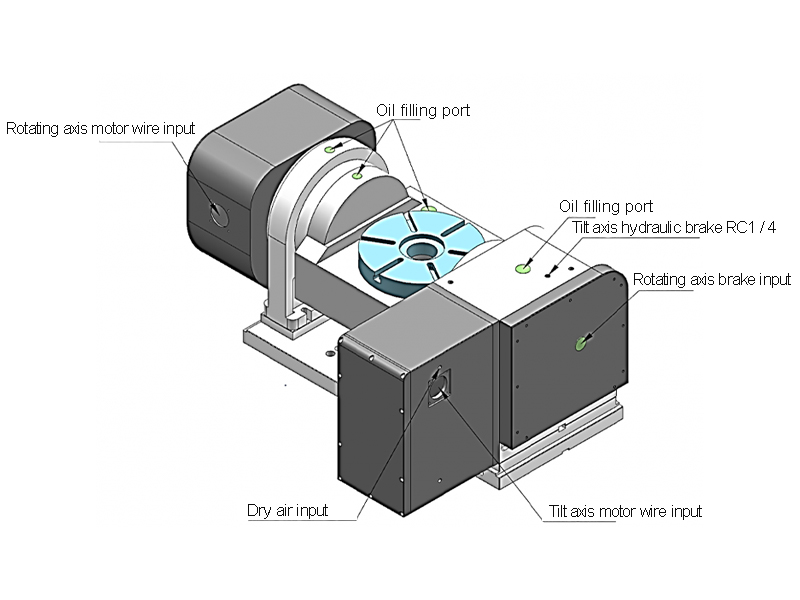

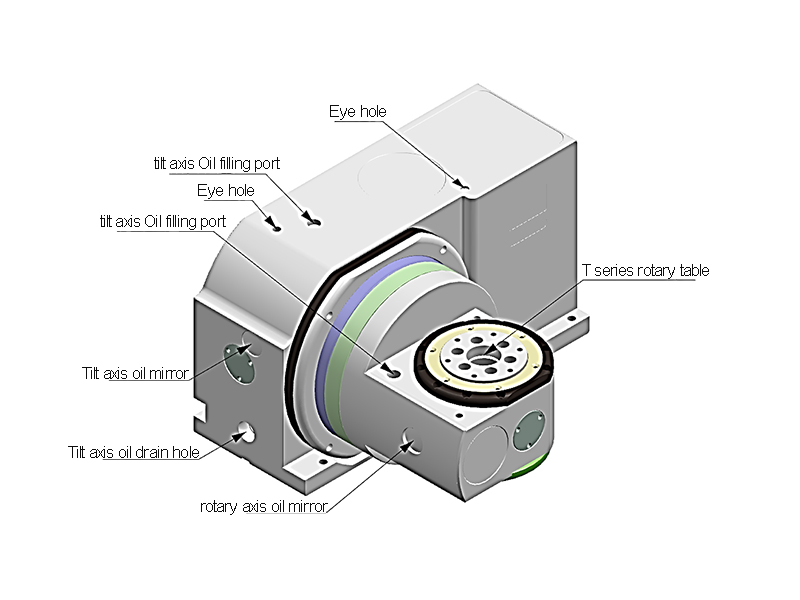

(三) . refueling position and drain position

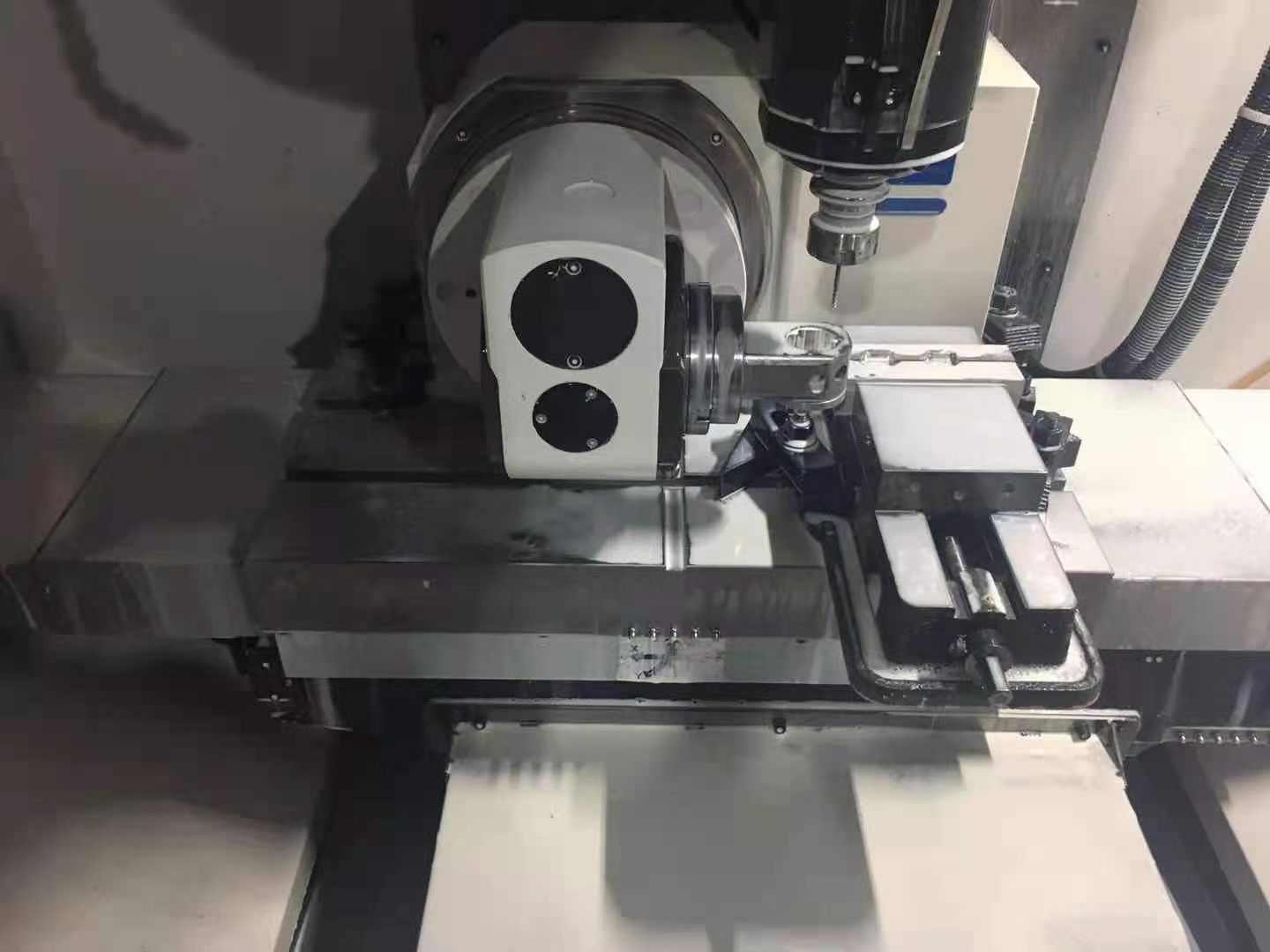

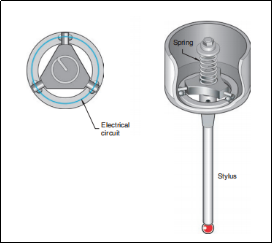

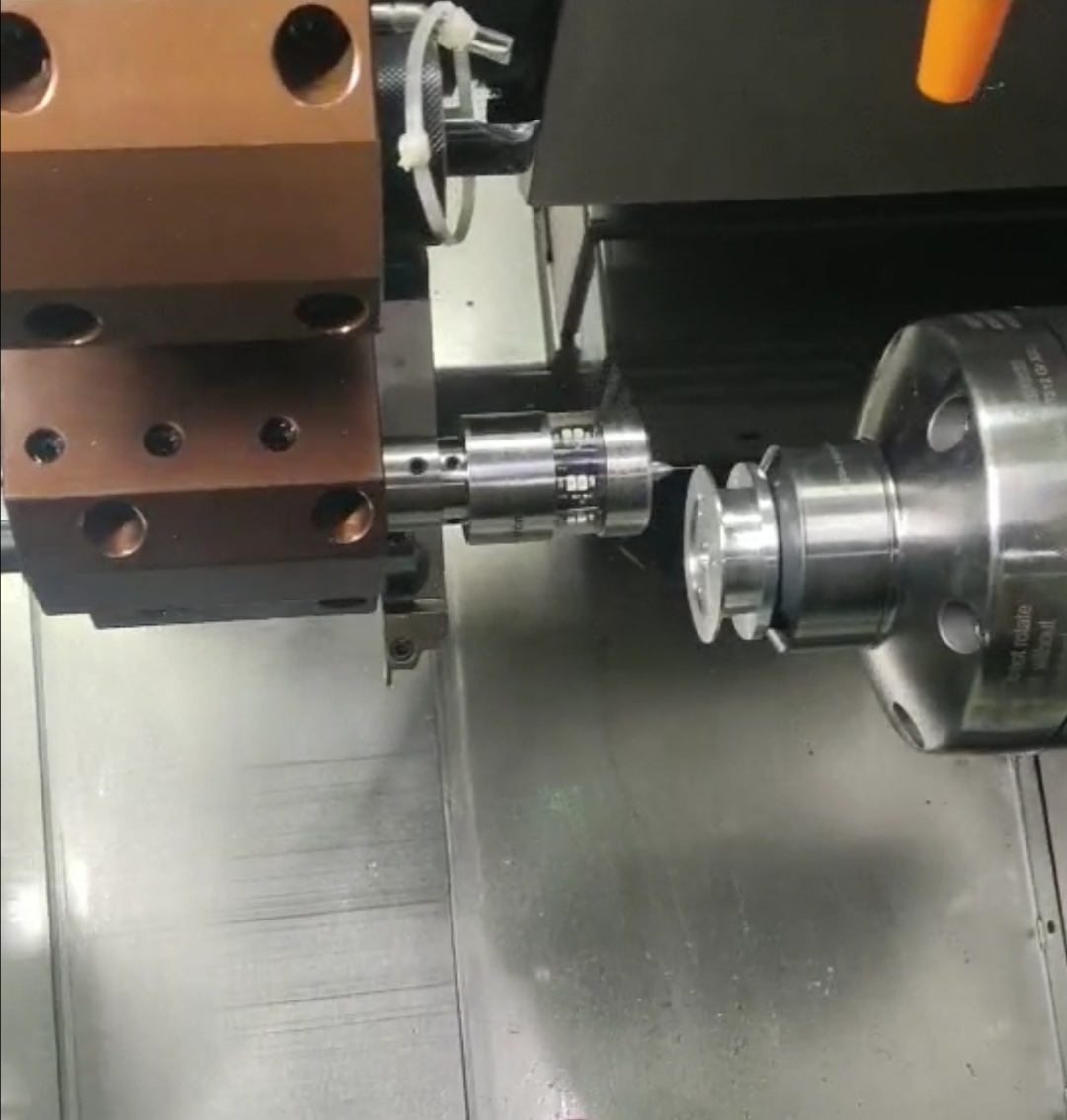

Open the manual attached to the turntable and find the item [lubrication] in the catalog. Operate according to the oil drain and oil inlet indicated therein. The turntable also has corresponding marks. The following is an example of the marks in the manual