Valuable machine tool accessories intruduce

Some accessories of machining centers are optional or installed when necessary. Generally speaking, these accessories can realize some special functions, improve the efficiency of machine tools, improve the yield of machining and reduce CT of the machining, here we intruduce some valuable accessories.

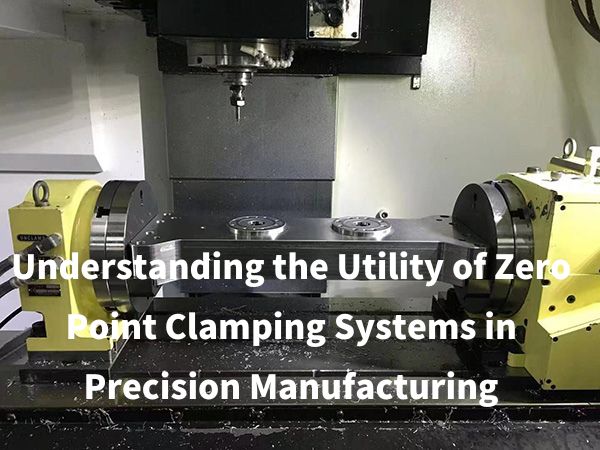

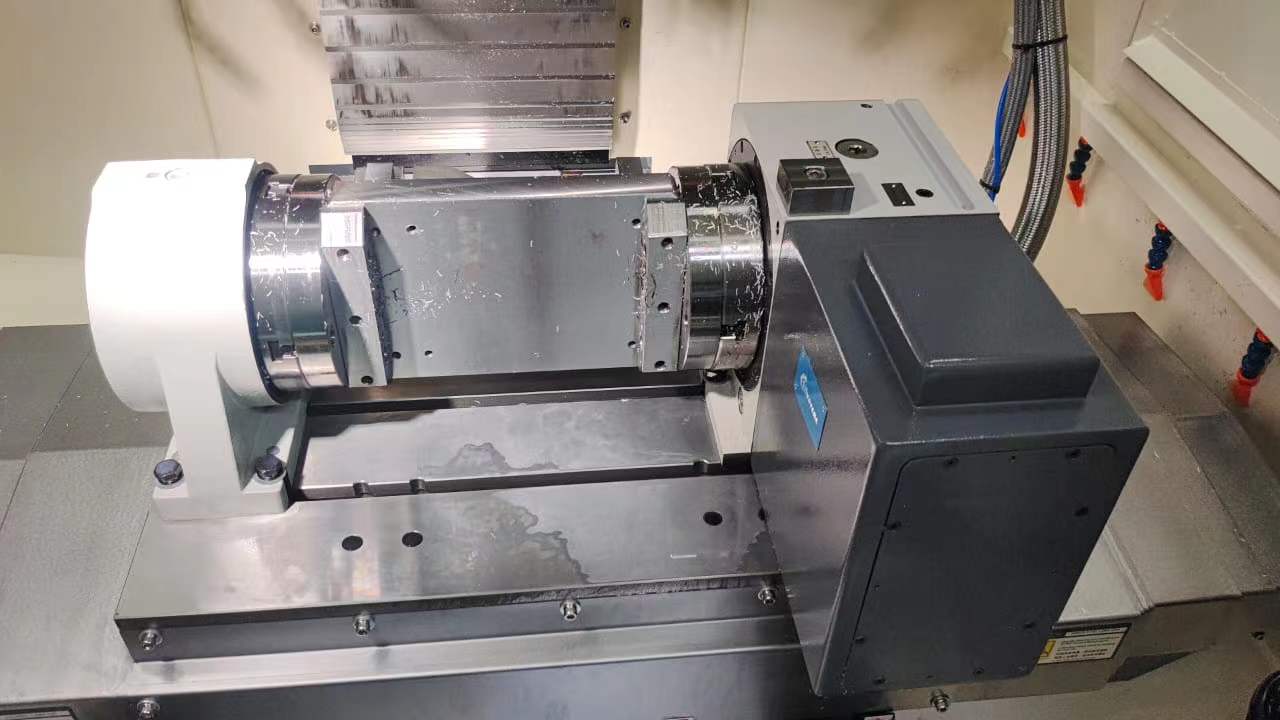

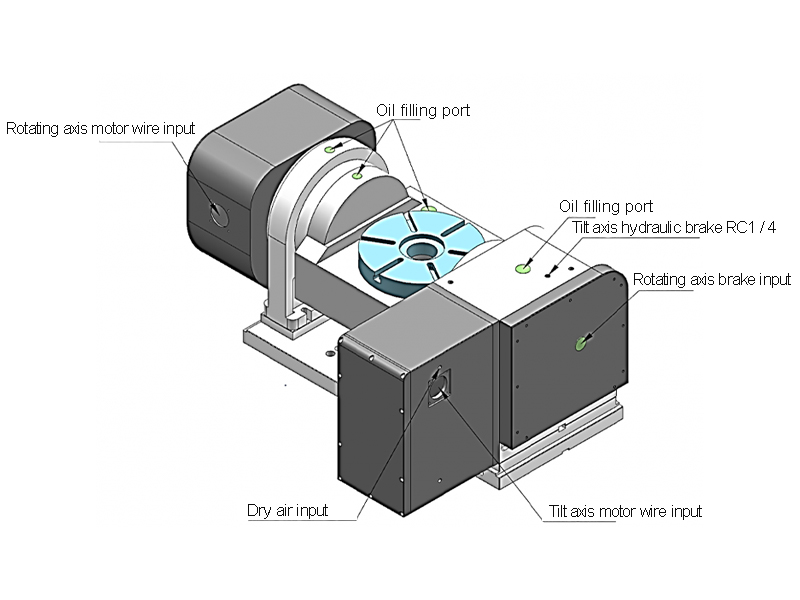

1.CNC rotary table

The rotary table includes 4 axis, 5 axis tilting table and horizontal table. According to different machine tool models and control systems, different motor drives are configured to interact with the machine tool to realize multi axis processing, complex parts can be processed at one time.

The ortary table includes three structure: worm gear, roller cam , motor derect drive.The three structures have their own advantages and disadvantages, Users can choose the appropriate table according to their own situation.

Main brand include: Nikken, Haas, Tudakoma, Kitagawa, Lehmann, Detron, TJR, SAMCHULLY and so on

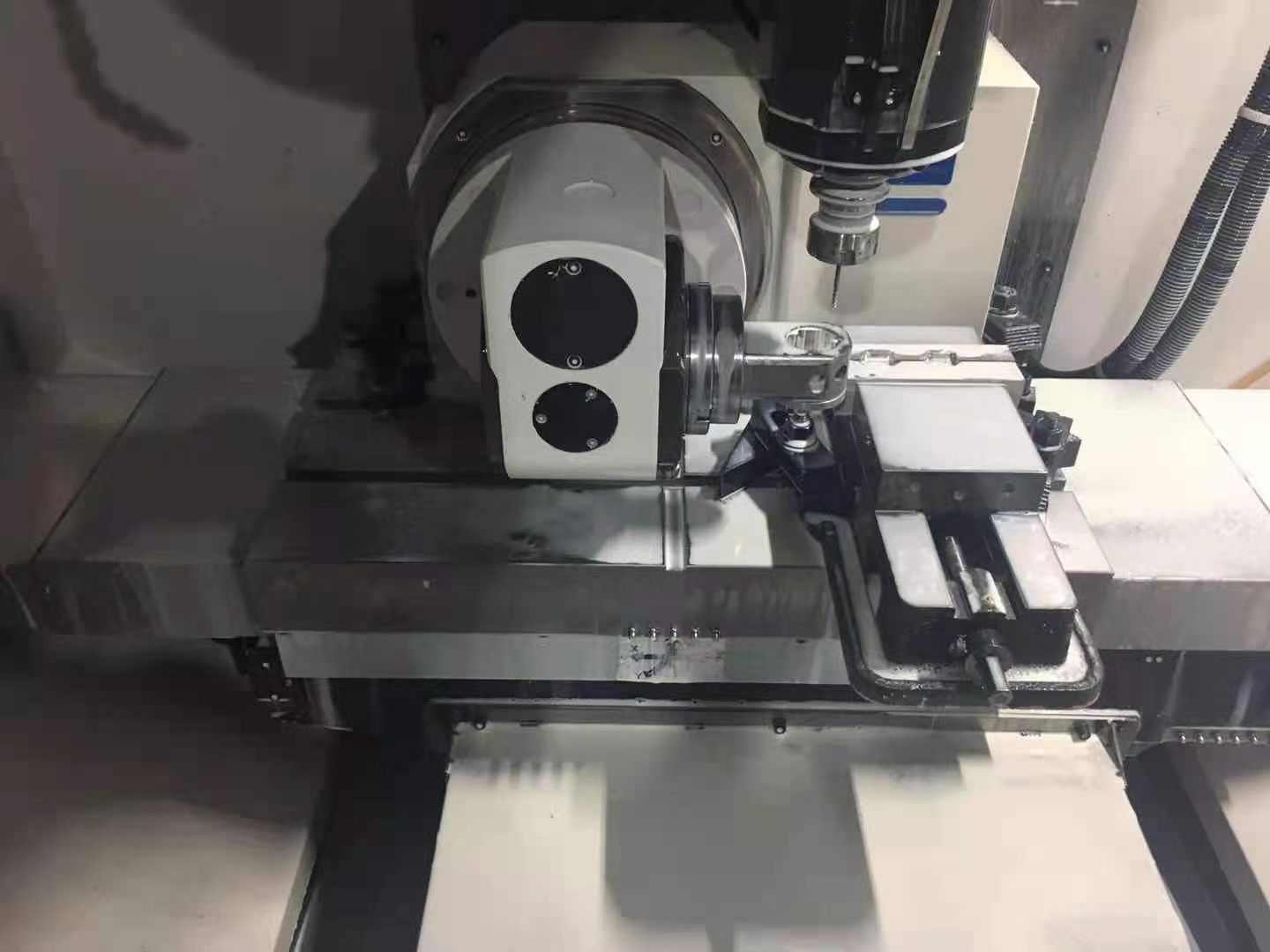

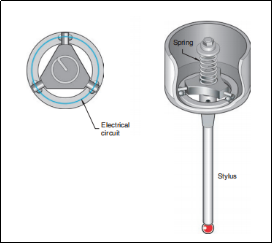

2. Machine tool inspection probe

The tool or workpiece size and position can be measured with machine tool probe , according to the measurement results correct the workpiece or tool offset amount automatically , so that the same machine tool can machining higher precision parts.

Probe signal transmission can be divided into infrared, radio, wired.

There are several well-known brands on the market: Renishaw, Blum, Marposs, Heidenhain, Metrol. Due to the high price, companies could not afford to use them. A cost-effective probe has been developed by Silvercnc, which not only meets the machining requirements, but also reduces the user’s cost. It has been widely recognized in the China market.

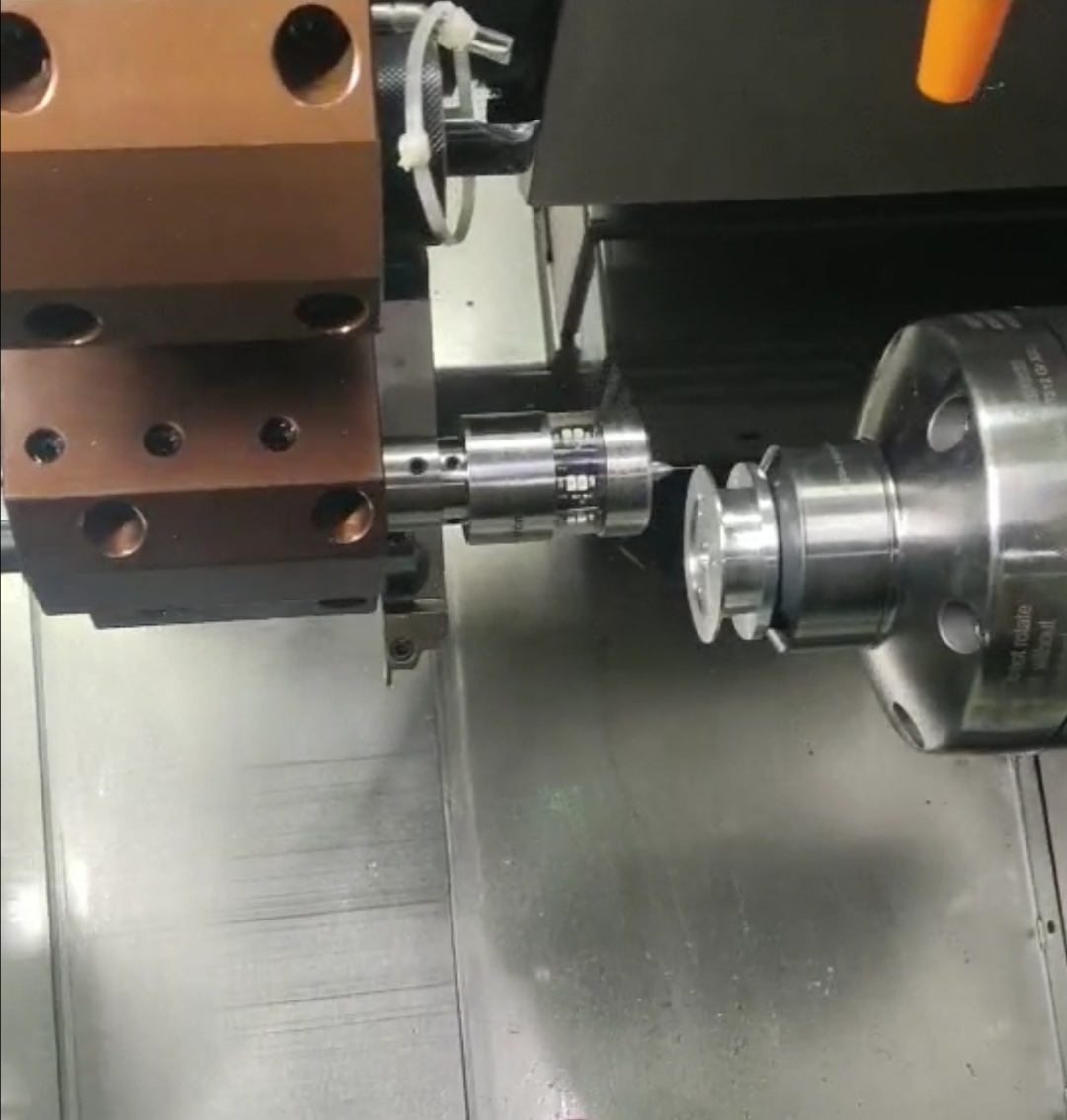

3. Angle head

The angle head of machine tool is mainly used in machining center and gantry milling machine. By using the angle head, the machining range and adaptability can be increased without changing the structure of the machine tool, so that some machining difficult to be completed by traditional methods can be realized, the repeated clamping of workpieces can be reduced, and the machining accuracy and efficiency can be improved.

4. Tool setter

The tool setting is installed on the machine tool to measure the tool length, diameter, wear and damage detection. It can automatically set the offset value of the tool to the workpiece coordinate system, so as to establish the workpiece coordinate system automatically. In this way, the setting of workpiece coordinate value can be easily realized, which not only saves time, but also improves efficiency. My suggestion is that each machine tool should be equipped with the tool setter

According to the structural principle, it can be divided into contact type, photoelectric type and laser type. The accuracy and tool diameter measurement are different.

There are several well-known brands on the market: Renishaw, Blum, Marposs, Metrol.