Six steps to solve the tool setting of machining center

1. Return to zero (return to machine zero)

Before setting the tool, be sure to return to zero (return to the machine tool origin) so as to clear the coordinate data of the last operation. Note: X, y and Z axes need to be zeroed.

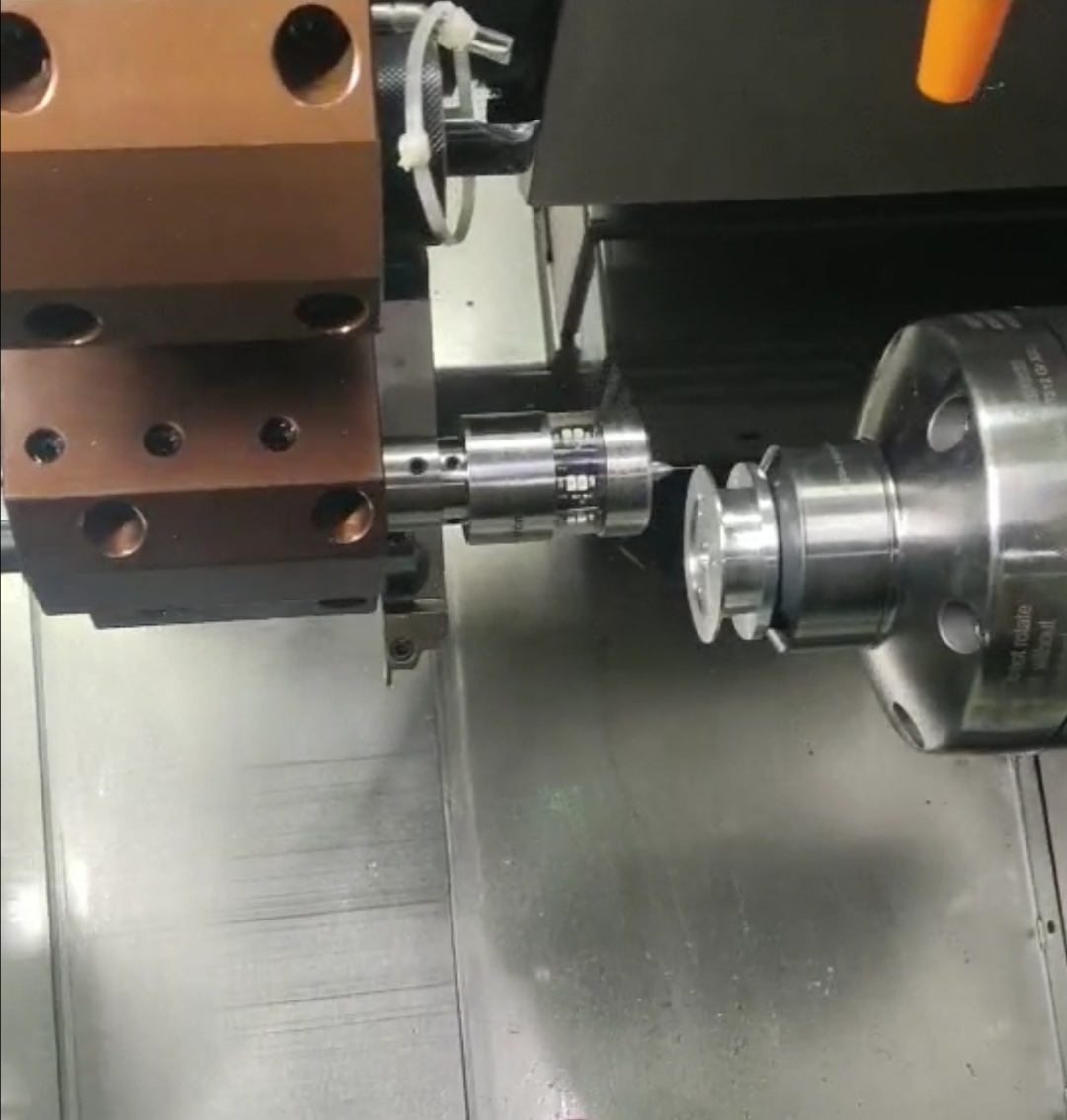

2.Spindle forward rotation

In “MDI” mode, by entering the instruction code to make the spindle rotate forward and maintain the medium rotation speed. Then change to “hand wheel” mode to move the machine tool by changing the adjustment rate

3.X-direction tool setting

Gently touch the tool on the right side of the workpiece to clear the relative coordinates of the machine tool; Lift the tool along the Z direction, then move the tool to the left of the workpiece, move the tool down to the same height as before, move the tool to gently contact the workpiece, lift the tool, write down the x value of the relative coordinate of the machine tool, move the tool to half of the relative coordinate X, write down the x value of the absolute coordinate of the machine tool, and press (input) to enter the coordinate system (FANUC system enters “x0.” and press “Measure” can also be used)

4.Y-direction tool setting

Gently touch the tool in front of the workpiece to clear the relative coordinates of the machine tool; lift the tool along the Z direction, move the tool to the back of the workpiece, move the tool down along the Z to the same height before, move the tool to gently contact the workpiece, lift the tool, record the y value of the relative setting mark of the machine tool, move the tool to half of the relative coordinate y, and record the y value of the absolute coordinate of the machine tool And press (input) to enter the coordinate system (FANUC system enters “x0.” and press “Measurement”).

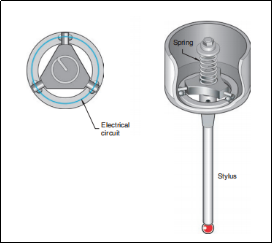

5.Z-direction tool setting

Move the tool to the surface of the workpiece where the zero point in Z direction is to be set, and slowly move the tool to slightly contact with the upper surface of the workpiece. Write down the Z value in the coordinate system of the machine tool at this time, and press (input) to enter the coordinate system (FANUC system can input “Z0.” or press “measure”).

6.Spindle stop

First closed the spindle, move the spindle to the appropriate position, choose the processing program and prepare for formal machining.