Wireless Infrared Tool Setter

Wireless infrared 3D Touch trigger tool setter for tool length and radius measurement, reduce setup times, perform in-process inspection

3D touch-trigger tool setter with infrared signal transmission in CNC machining centers, Precise and reliable tool measurements similar to a infrared touch probe.

Brand: SILVERCNC

Models: SOTS

Logo printing : Silvercnc/WDS/None/Customized

Surface finishing: Grinding 4s

Repeatability: 1um

Contact life: 10million

Contact materia: Tungsten carbide

Signal: infrared

Warranty: 1 year

Packaging Details: carton

Shipping: DHL/TNT/UPS, 3-7 days

modulated Design of wireless tool setter

■ SOTS assemble with a SOMP40 Probe, bracket and stylus kits.

■ Wireless tool setter SOTS and infrared touch probe SOMP40 can share the same receiver SIR.

■ Run different macro programs to achieve modular application of spindle probe and tool probe.

■ Cable free, easy to install and remove.

SOTS Tool setter benefits

■ High machining accuracy requires an exact measurement of tool data and cyclical inspection of tool broken and wear.

■ With the SOTS tool setter,engineer can setting the tool automatic, setter up faster, improve quality and reduce scrap.

■ Using the SOTS to measure tools wear and tool breakage monitoring, the machine will alarm automatic when exceeding allowable value, reminding tool compensation.

■ Automatic operation, save labor, prevent the emergence of substandard products

■ Applicable to the Engraving machine and all kinds of control machinery in Japan, Taiwan, South Korea, China, Germany. Such as fanuc, SYNTEC, Baoyuan, Siemens, FAGOR, Mitsubishi, etc.

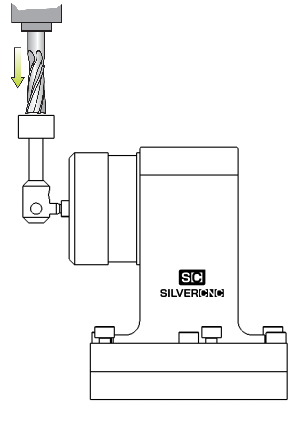

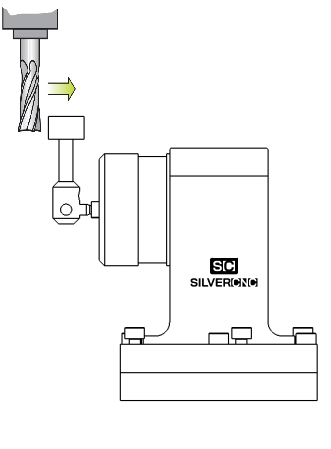

Automated tool setting

Establish height offsets and check tool length is within tolerance

Determine diameter when spinning to establish tool size offsets

Manual setting errors and data entry

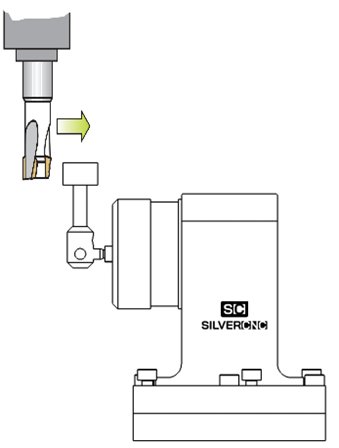

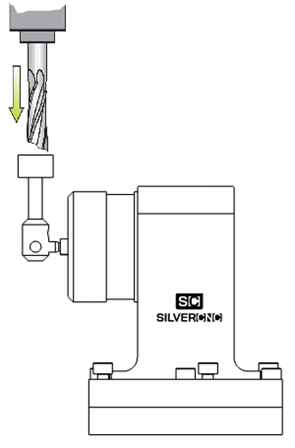

In-process control

Detect broken tools in-process

Compensation of tool wear using measurements between the machining steps.

Tool length measurement

Tool radius measurement

Tool wear measurement

Tool breakage monitoring

SOTS Wireless tool setter Specification

Model | SOTS |

Output | NO(Normally open) |

Sense directions | 5 axis |

Pre-travel | 0 |

Travel | +/-12.5°, Z-6.35mm |

Repeatability | <1um |

Trigger life | >10million |

Protect | IP68 |

Contact force | 0.4N~0.8N, Z-4.0N |

Signal transmission | Infrared |

Contact material | Tungsten carbide |

Surface finishing | Grinding 4s |

Rated voltage and current | DC24V 20mA |