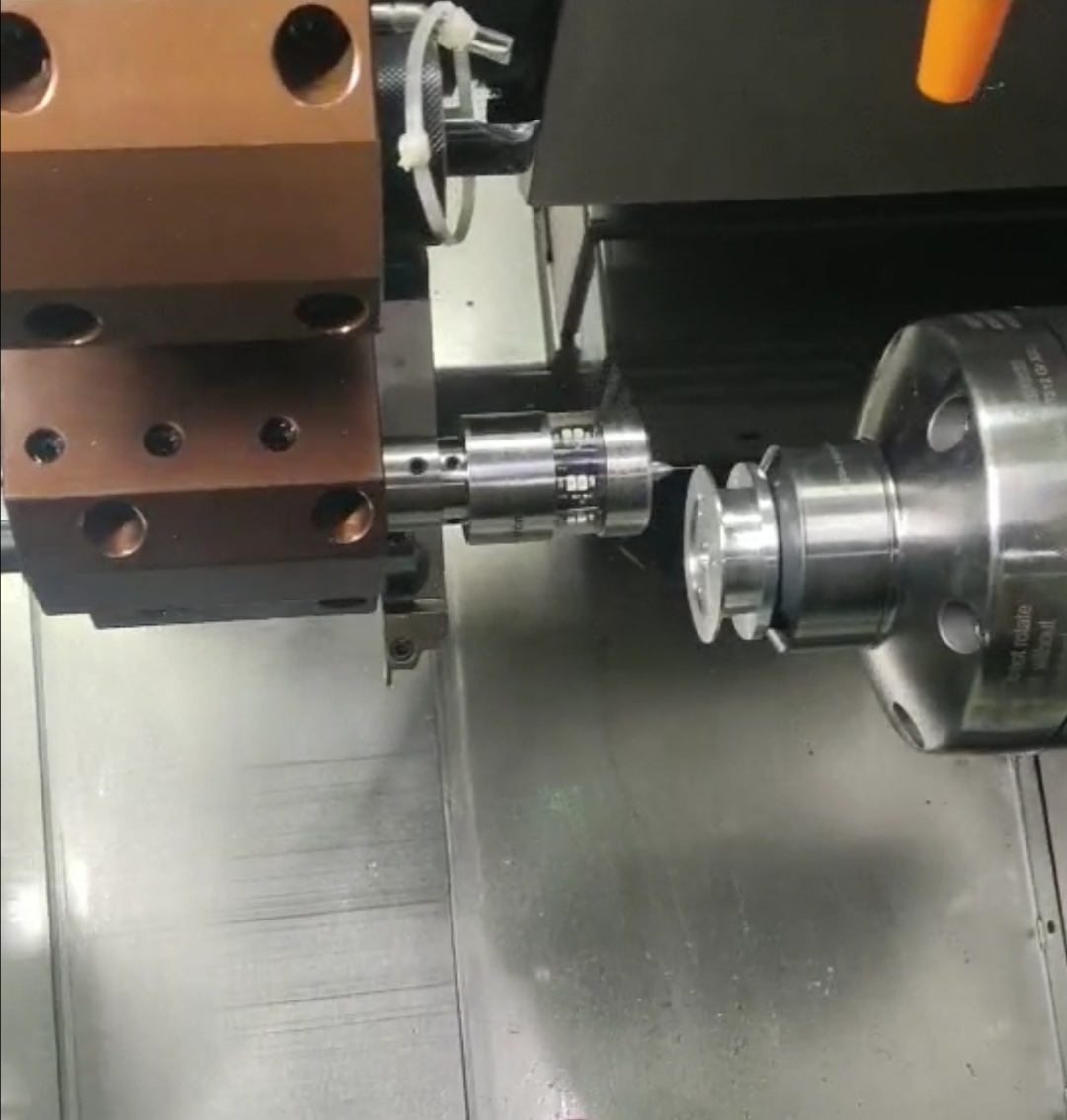

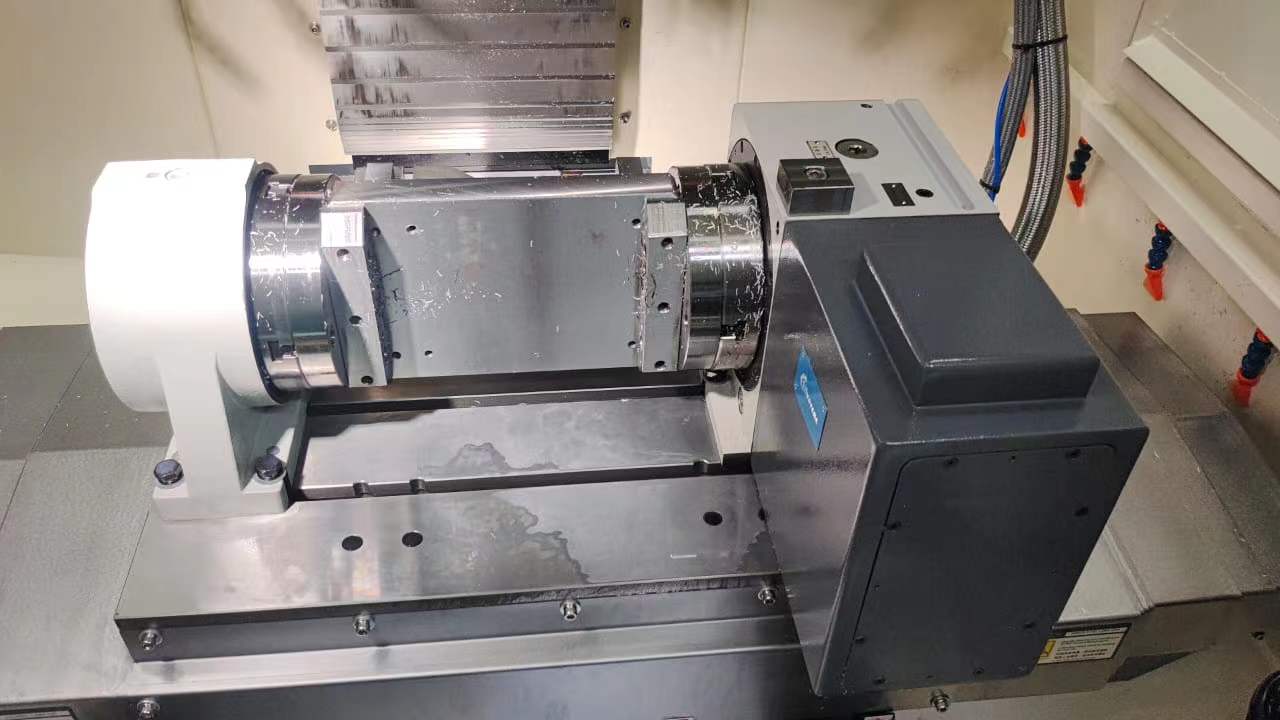

CNC touch probe application on turret and grinder

Machining requirement

When machining on turret and grinders, the dimensional deviation caused by the wear of cutting tools and grinding wheels or the position error of workpiece clamping. Such as outer circle, inner circle and other dimensions. The general accuracy is required to be 0.01 – 0.03mm.

Difficulties in machining

● the concentricity of machining or cylindrical grinding clamping is unstable

● cumulative wear of cutting tools and grinding wheels

● instability caused by product clamping deflection

● large scale deviation of batch products

● datum deviation caused by workpiece clamping

Touch probe solution

Radio probe drp40+ standard macro program + customized measurement main program. After fixing the workpiece in the fixture, measure and align the outer circle, inner circle or z-axis position of the workpiece by calling the measurement program and machine tool probe, find the actual position of each product, and automatically update the actual position value to the machining coordinate system to realize automatic setting of machining benchmark. Or workpiece size measurement after machining.

Application benefits

After the application of the machine tool equipped with touch probe and measurement program, the dimensional stability of the processed workpiece is ensured and the yield of the product is improved. At present, in the application of high-precision machining and cylindrical grinding, the probe can greatly improve the dimensional stability of products.