Machining efficiency improvement of the fourth fifth axis

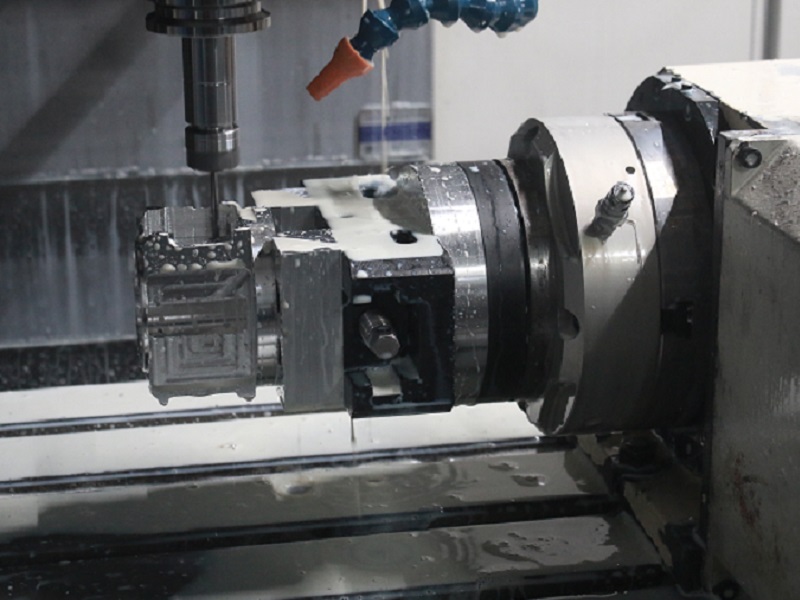

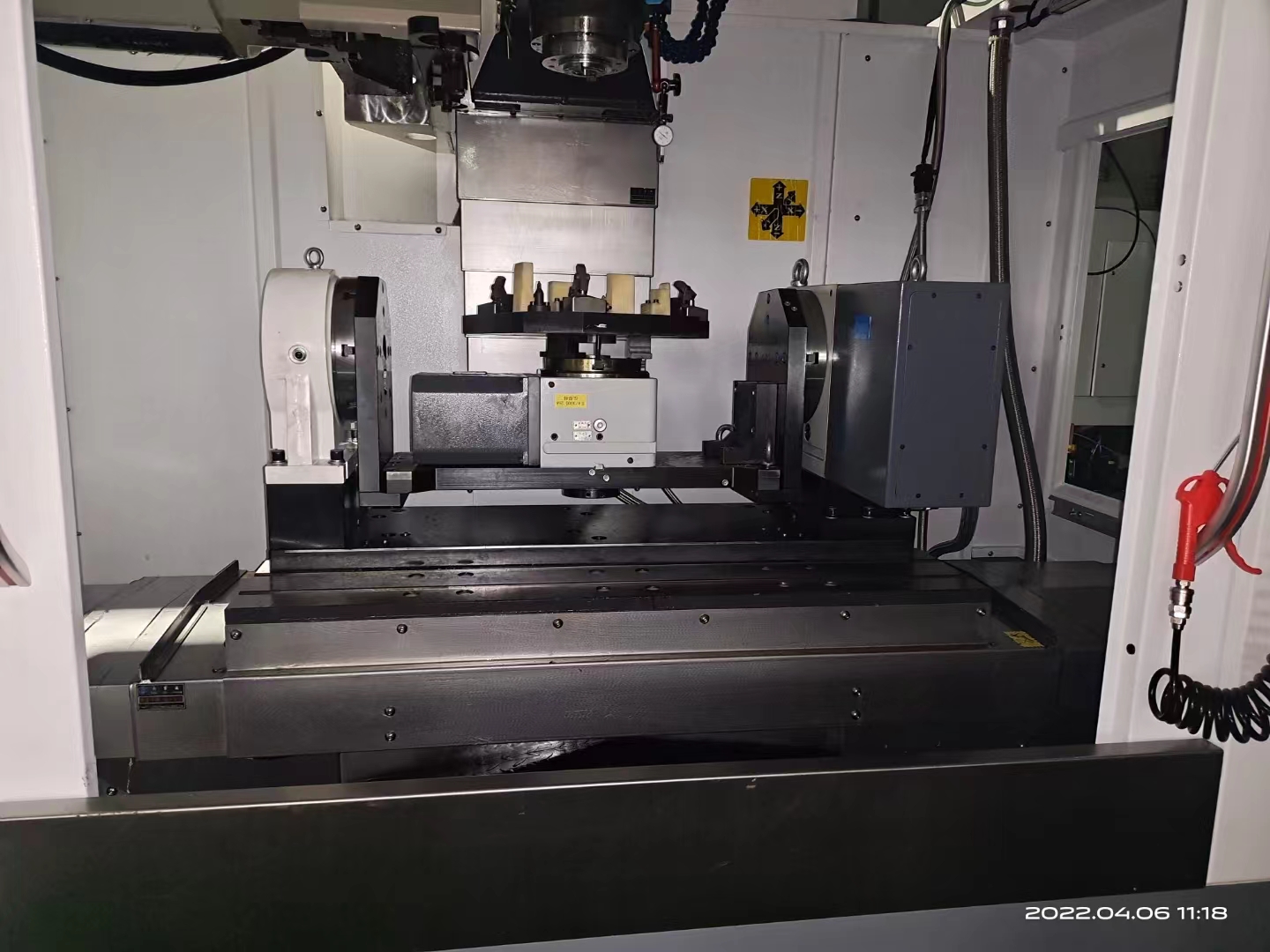

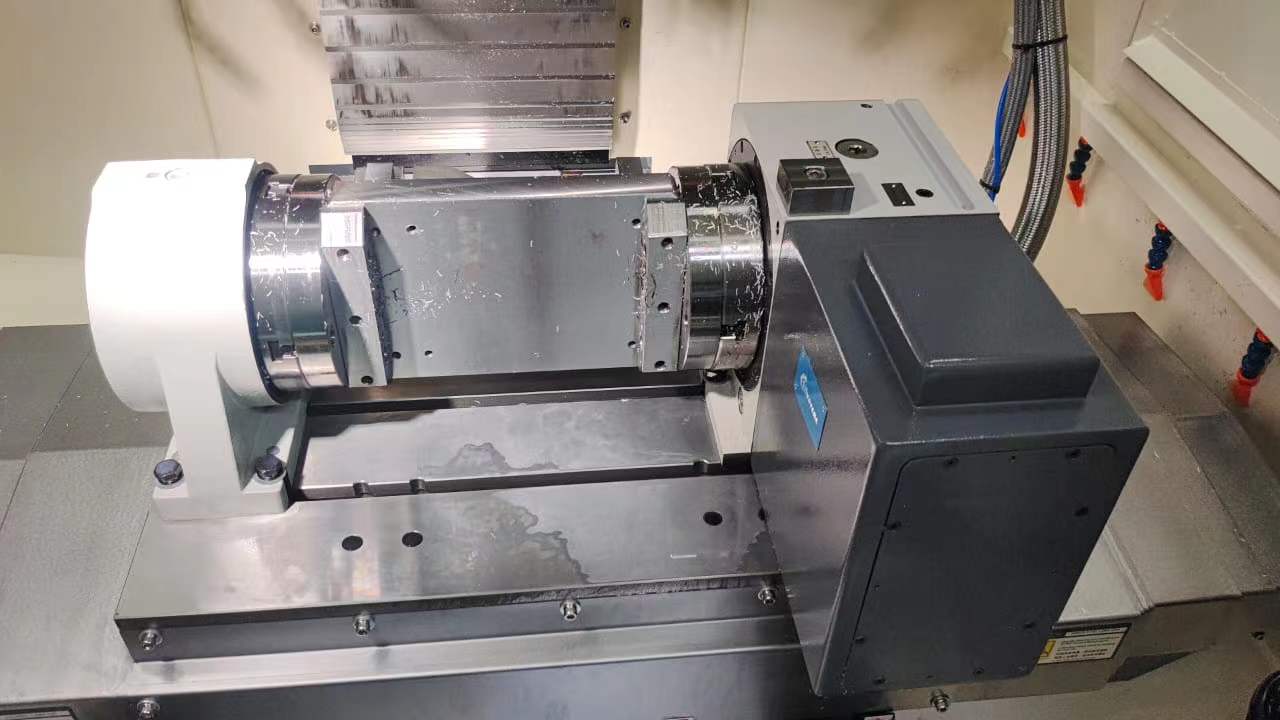

The machining efficiency of three-axis NC machine tools can be improved by adding the fourth axis and the fifth axis. The turntable can expand the original processing space through accurate positioning. The well-designed fixture can not only improve the processing efficiency, but also reduce the idle of the machine, and the operators can draw themselves out of it.

To machine the first three faces of such a part, if the clamping mode of vice is used, it takes a total of 264 seconds for each part (excluding the clamping time)

By designing more compact fixtures and making full use of the processing space provided by the turntable, you have the opportunity to process 28 parts at a time.

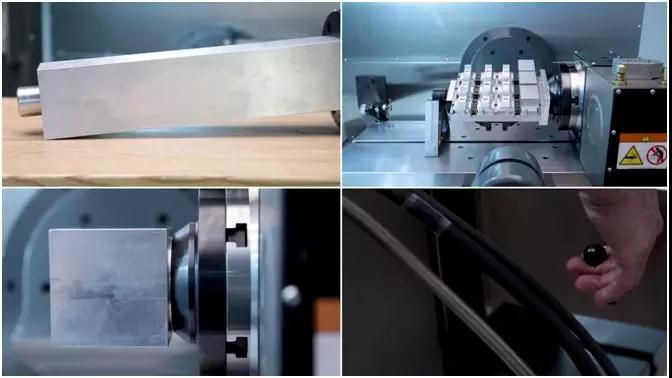

In the production of the fixture, an aluminum alloy with a size of 114mm * 114mm * 550mm is selected as the matrix, the positioning pin is selected as the positioning, and the compression fixture occupying less processing space is selected for faster clamping.

Then mill the four surfaces of the base, and process a locating pin hole for each part, two slots for avoiding the empty locking fixture, and two threaded holes for locking, which are all the manufacturing steps.

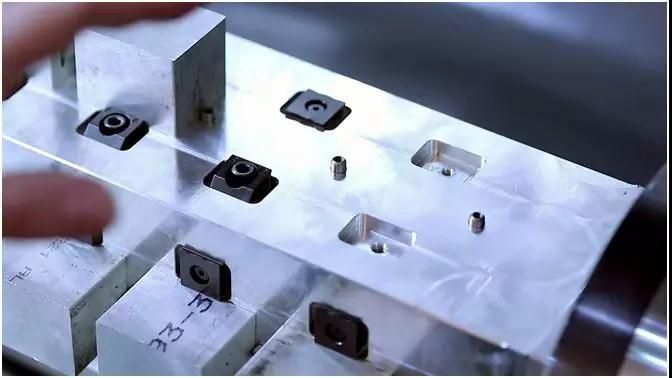

- 28 locating pins

- 56 positioning and locking blocks (reusable)

- 56 screws

- There is also a wrench for weighing hands

This is all the components of this fixture.

This fixture design can shorten the original processing time from 264 seconds to 202 seconds (regardless of clamping time).

This means that the processing time has been reduced by 23.5%

Moreover, since the machining program has combined the three machining surfaces of the part into one machining program, the cycle time of a single program becomes 95 minutes. During this period, the machine has been processing without waiting for frequent clamping by the operator. There is no doubt that this will greatly reduce the labor intensity of operators.

The article was created by HAAS